Contact Your NewwaySMTC Representative Now! DuncanLi@newwaysmart.com

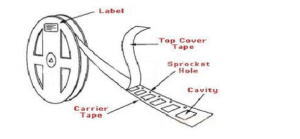

Application of raw materials for carrier tape

As we all know, there are numerous classifications of carrier belts, each of which has different raw materials and can be used for a wide range of applications.

The following are the categories of raw materials for carrier tape

Carrier sheet material categories: PS material; PC material; ABS material; single-layer material; three-layer material. Material properties: PS transparent material; PS conductive material; PC transparent material; PC conductive material; ABS conductive material; single-layer material; three-layer material; PC material has higher toughness and strength, ABS has better strength, and PS has general strength.

The function of raw materials for carrier tape

Electronic product packaging requires high antistatic performance of the material, which is prone to static electricity during the packaging and transportation of electronic products. The top cover tape can be divided into three types according to the electrical properties of the material: anti-static type, conductive type and insulating type. Conductive top cover with a surface resistance value of 104 ~ 106Ω; because of the low resistance value, anti-static products with conductive function, can discharge static electricity. Anti-static upper cover with a surface resistance value of 105 ~ 1012Ω; insulated upper cover with a surface resistance value of 1012Ω or more. Easy to generate static electricity and can not discharge itself. Antistatic polystyrene sheet can also be obtained by external application of antistatic agent and internal addition of antistatic agent in two ways. The way of external antistatic agent coating process is simple, antistatic effect is good, the material cost is low.

The surface is high gloss, polystyrene packaging sheet polystyrene packaging sheet is mostly toughened with impact-resistant polystyrene resin, sheet transparency is low, the surface of the material is usually matte.

For some daily chemical products polystyrene packaging, in order to improve the aesthetics of the packaging, to promote the sale of goods, the material surface with a high gloss.

Preparation of surface glossy polystyrene sheet usually take a multi-layer composite structure, the material surface layer using a high transparency of butylbenzene transparent impact resistance resin or general polystyrene, as the composite resin layers due to inconsistent melt flow rate, in order to make the distribution of each layer is uniform, the control of the molding process is very critical.

The core of the carrier belt to enhance the interest is the equipment and raw materials, to get good quality of the carrier belt, to the carrier belt raw materials this bottom to do a good job.