Contact Your NewwaySMTC Representative Now! DuncanLi@newwaysmart.com

SMD carrier tape ——High speed capacity, On-time delivery ——High quality supplier

In terms of supplying carrier tapes, Newwaysmart has always insisted on the high speed-production capacity for customers who need it and has always made products in a highly efficient way, giving customers orders overtime while ensuring high-quality products. With this, Newwaysmart has gained a group of loyal customers with the title of a quality supplier.

Let’s learn about the high speed capacity of SMD carrier tape

Our company is mainly engaged in carrier tape products, including SMD carrier tape, carrier tape material production equipment:The equipment for carrier tape is also called carrier tape forming machine. At present, there are mainly two types of carrier tape forming machines.

Roller type and flat type

The difference between the two is the difference in their molding molds

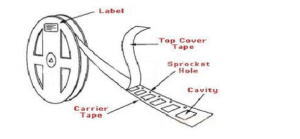

SMD carrier material refers to the plastic carrier that is widely used for packaging SMT electronic components such as IC, resistors, inductors, capacitors, connectors, LEDs, fuses, switches, relays, connectors, oscillators, diodes, transistors, etc. The production materials of SMD carrier material mainly include: PSSMD carrier tape, ABSSMD carrier tape, PETSMD carrier tape, PCSMD carrier tape, HIPSSMD carrier tape, etc. HIPSSMD carrier tape and other plastic materials, and special requirements can use metal manufacturing. The raw materials for each type of SMD carrier tape are different. Let Newwaysmart take you to know more about them.

The material of carrier tape mainly includes two types: plastic (polymer) and paper. Embossed carrier tape is mainly composed of plastic materials, the mainstream of the market is PC (Polycarbonate, polycarbonate) carrier tape, PS (Polystyrene, polystyrene) and ABS (acrylonitrile-butadiene-styrene copolymer resin) carrier tape, in addition to a small number of PET, APET and other materials prepared by the carrier tape. Stamped carrier tapes are mainly made of paper or PE composites.

PC material is characterized by high mechanical strength, good transparency, good dimensional stability, high glass transition temperature, and good heat resistance; PS material has lower mechanical strength than PC material, so it is sometimes made into a three-layer composite sheet with ABS material to improve the tensile strength of the carrier tape; PET material has a mechanical strength close to PC, but is a crystalline material with poor dimensional stability.

So in summary, the customer will mainly be based on the number of components, size, functional categories, SMT equipment requirements and design of the carrier tape cavity to consider the length of the carrier tape, carrier tape width and carrier tape material. Also will be through the visibility requirements to choose whether you need transparent color material, as well as the depth and strength of the cavity to consider the selection of the thickness of the carrier tape, so as to determine the final design and manufacture of the carrier tape. Although carrier tape is only used as an auxiliary material for component packaging, some highly transparent and conductive materials have been developed and put into production for our carrier tape products to meet the needs of high-speed, high reliability and high- precision assembly of special components. We can match the size and shape of the component, and customize the width and thickness of the selected material with our customers.