Contact Your NewwaySMTC Representative Now! DuncanLi@newwaysmart.com

Electronic component packaging plays a protective role in the electronics industry and belongs to the “dry goods”

There are many types of Electronic component packaging, commonly used electronic components are resistors, inductors, capacitors, potentiometers, transformers, amplifiers, switches, etc.

Electronic component packaging can protect products from damage

Before packaging, we should know the location of the metal that needs to be protected by electronic components, consider whether it applies to your components when choosing the right packaging method, and also pay attention to the quality of the selected package material, material, etc.

The role and application of electronic components packaging

The packaging can not be easily deformed or squeezed components, so as not to cause pin deformation damage, in addition to electronic components packaging should also require anti-static treatment. Electronic component packaging plays a protective role in the electronics industry and belongs to the “dry goods”. There are many types of Electronic component packaging commonly used electronic components are resistors, inductors, capacitors, potentiometers, transformers, amplifiers, switches, etc. Before packaging, we should know the location of the metal that needs to be protected by electronic components, consider whether it applies to your components when choosing the right packaging method, and also pay attention to the quality of the selected package material, material, etc. The packaging can not be easily deformed or squeezed components, so as not to cause pin deformation damage, in addition to electronic components packaging should also require anti-static treatment.

SMT chip components packaging is the entire SMT chip processing in a fairly important link

It directly affects the entire chip processing pipeline production efficiency.

Electronic components packaging forms

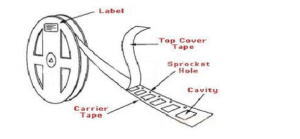

Electronic components packaging forms are mainly four, braided tape packaging (Tape and Reel), tube packaging, tray packaging, and bulk. SMT components and the development of the relationship with the carrier tape, in the last century SMT surface mount technology emerged so that electronic products to produce a huge change. SMT is widely used to promote the development of SMD surface-mounted devices.

The original jack-type components are replaced by SMD components become inevitable, while the small size of cell phones, computers, and other electronic products, multi-functional requirements to promote the development of SMD components to high integration, miniaturization. In addition to other transport carriers such as trays, plastic tubes, etc., SMD components must also be able to be used in SMT machines at high-speed automation required transport SMD carrier tape system. From the protection, economy, capacity and other aspects of the carrier system is also quite advantageous: this is why the majority of SMD components seen in the SMT production line carrier system are paper substrate and plastic substrate, the requirements of the carrier system! Device design requires a high degree of integration, production, and processing requirements of higher efficiency, making the vast majority of the current devices surface mount packaging.