Contact Your NewwaySMTC Representative Now! DuncanLi@newwaysmart.com

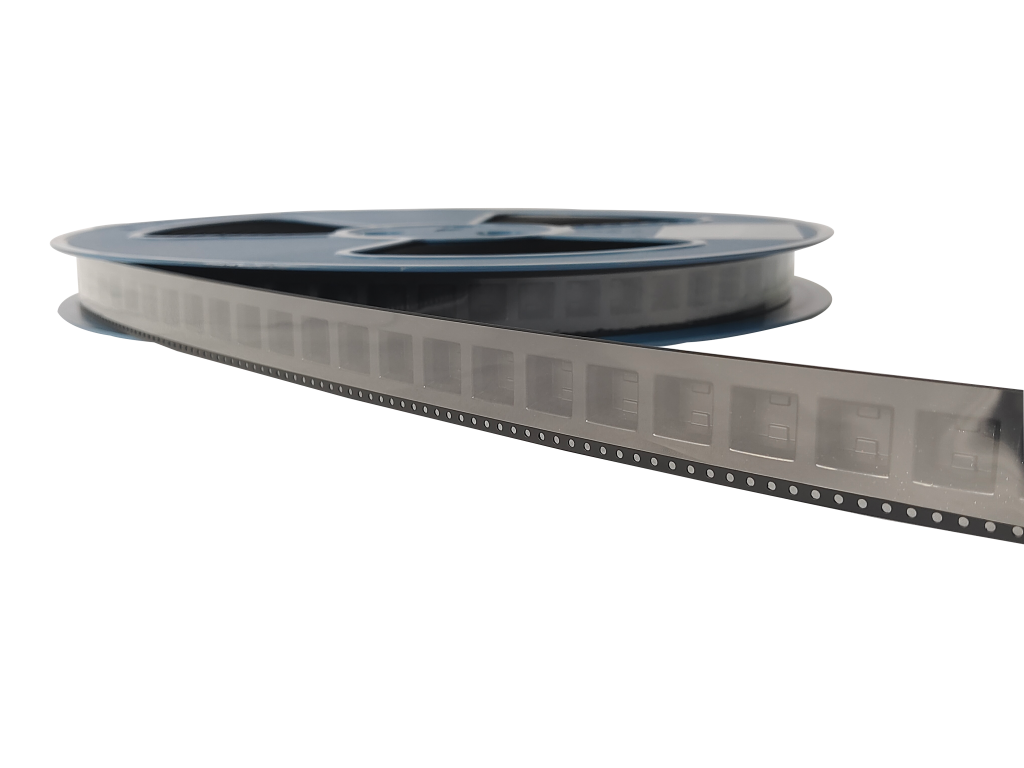

Introduction of SMD carrier tape for recyclable applications

Newwaysmart is a technology company specializing in providing special SMD carrier tape for the electronic components industry, and has been focusing on the carrier tape industry for eighteen years. We have strict requirements and control on SMD carrier tape, so SMD carrier tape can be recycled.

What are the important features of SMD carrier tape that can be recycled?

SMD carrier tape can be recycled applications, no harmful substances, no odor zero environmental pollution, green environmental protection.

SMD carrier tape credibility: anti-oxidation, waterproof and moisture-proof, in addition to odor and moth, effective flame retardant grade, the characteristics of long-term.

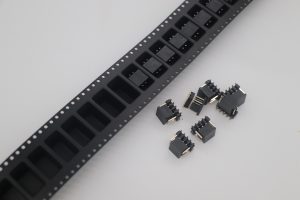

SMD carrier tape is commonly used in IC, semiconductor devices, dolomite crystal resonators, oscillators, resistors, inductors, power capacitors, RF connectors, LED, fuse tubes, power master switch, relays, RF connectors, diodes, transistors, cell phone shielding frame and other SMT electronic components products packaging carrier.

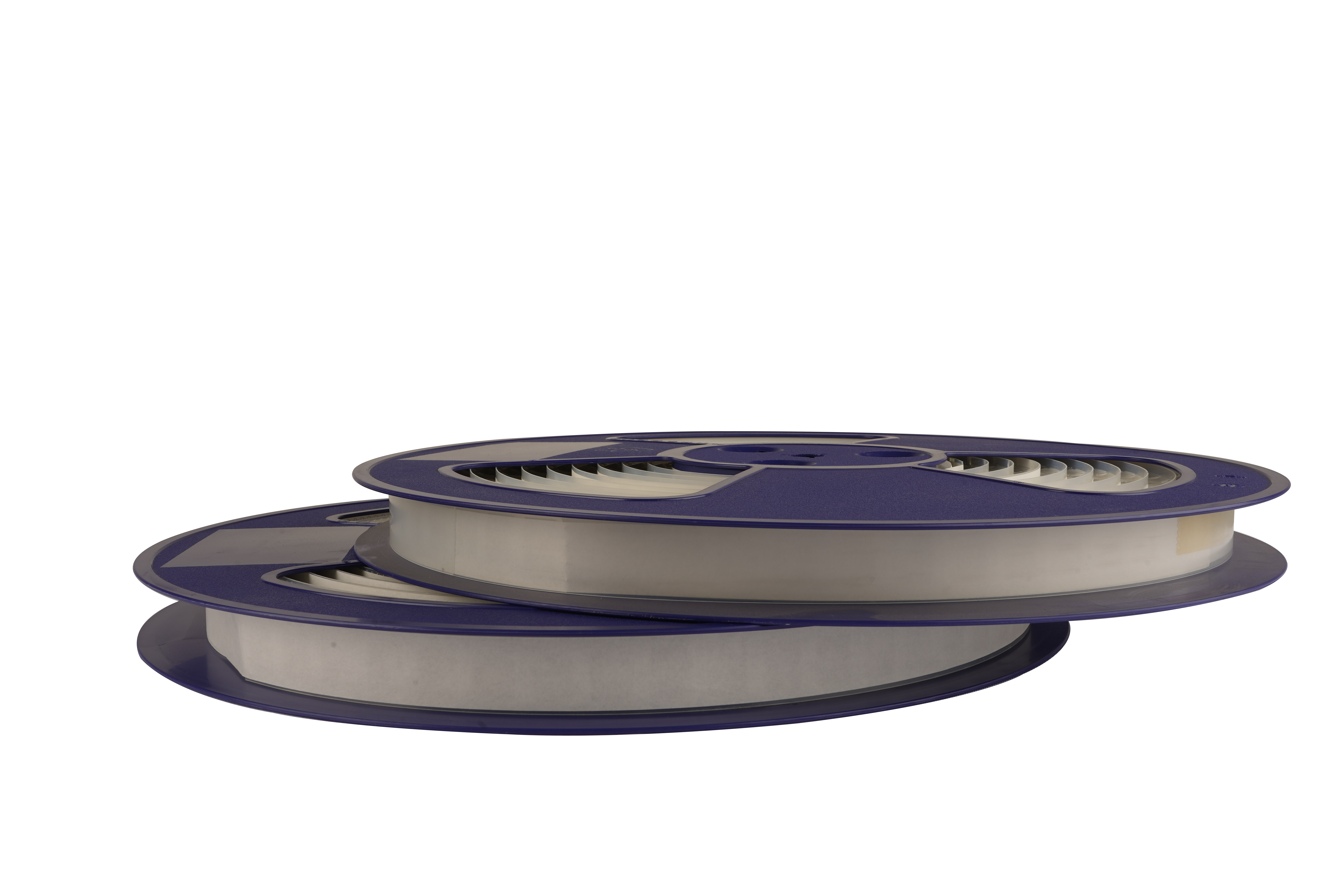

What is SMD carrier tape tray?

SMD carrier tape tray is a kind of adhesive tape tray to support the carrier tape.SMD carrier tape production is completed need to receive the adhesive tray, the receipt is needed to carry out the carrier tape and isolation tape at the same time, because the carrier tape is a plastic sheet with pockets, the molding part will be stacked together when carrying out the roll assembly, resulting in the deformation of the carrier tape to become scrap, so the isolation tape also has a role in the production of the carrier tape.

What is the use of barrier tape?

In addition to the protection of the belt, there is another role of the belt to help SMD belt products of dustproof role, because the isolation of the belt hole to ensure that the dust will not enter the belt hole, to ensure the clean loading parts, while ensuring the quality of the belt and parts quality. When SMD carrier belt is loaded with packaged products, the carrier belt drag tray is subjected to various forces in various natural environments such as transportation, and tensile strength is among them. In order to better ensure that the adhesive load tray bears the force in the whole process of manufacturing, shipping or delivery, and that the adhesive load tray is not easily destroyed, the adhesive load tray must bear a certain force value to ensure the safety of the loading belt. Resistance and stability testing is carried out by the tape media by loading the tape media onto the tape media. Double loading to ensure that the loaded tape media on the tape media is not easily destroyed, and to ensure the safety of electronic equipment, SMD carrier tape quality, and the role of the tape dragging plate, so the tape dragging plate reduction test for the tape packaging is also very critical.

What is the raw material of SMD carrier tape

There are two kinds of raw material key for SMD carrier tape: plastic (polymer) and stone. Embossed carrier tape is made up of plastic material. Popular in the sales market are polycarbonate carrier tape, polyethylene and acrylonitrile-butadiene-butadiene polymer carrier tape. In addition, there are also some carrier tapes made of polyester, APET and other raw materials. Stamping die carrier tapes are mainly made of paper material or high pressure polyethylene polymer material.

Main Applications of SMD Carrier Tape

The main uses of SMD carrier tape can be divided into; IC chip special carrier tape, crystal transistor special carrier tape, RF transceiver light-emitting diode special carrier tape, RF transceiver inductor special carrier tape, integrated chip carrier tape, RF transceiver capacitor special carrier tape, chip RF connector special carrier tape, etc..

Because SMD carrier tape is fully automatic transmission and packaging parts in the electronics industry medium, electronic parts manufacturers to manufacture and package electronic parts, it is imperative that they are shipped to customers, which is difficult to avoid the delivery of the whole process of rude delivery, and even in the delivery and air parts of the whole process of collapse of goods, which is likely to cause the destruction of the carrier tape system software. This stipulates that the SMD carrier belt should have excellent impact resistance. In order to better prevent such problems caused by consumer complaints, to improve the carrier belt drop test has become the carrier belt manufacturing enterprises preferable problem. This can help everyone’s customers to prevent falling and destroying goods, really reduce costs and reduce consumer complaints.