Contact Your NewwaySMTC Representative Now! DuncanLi@newwaysmart.com

Advanced semiconductor packaging material solutions

As the need for smaller, thinner components and multi-layer chip stacks rises, and the number of individual chips that can be tracked in a SIP package continues to grow, effective solutions are needed to reduce the rate of loss during chip transport from storage to the SMT machine for wafer-level chip packaging (WLCSP).

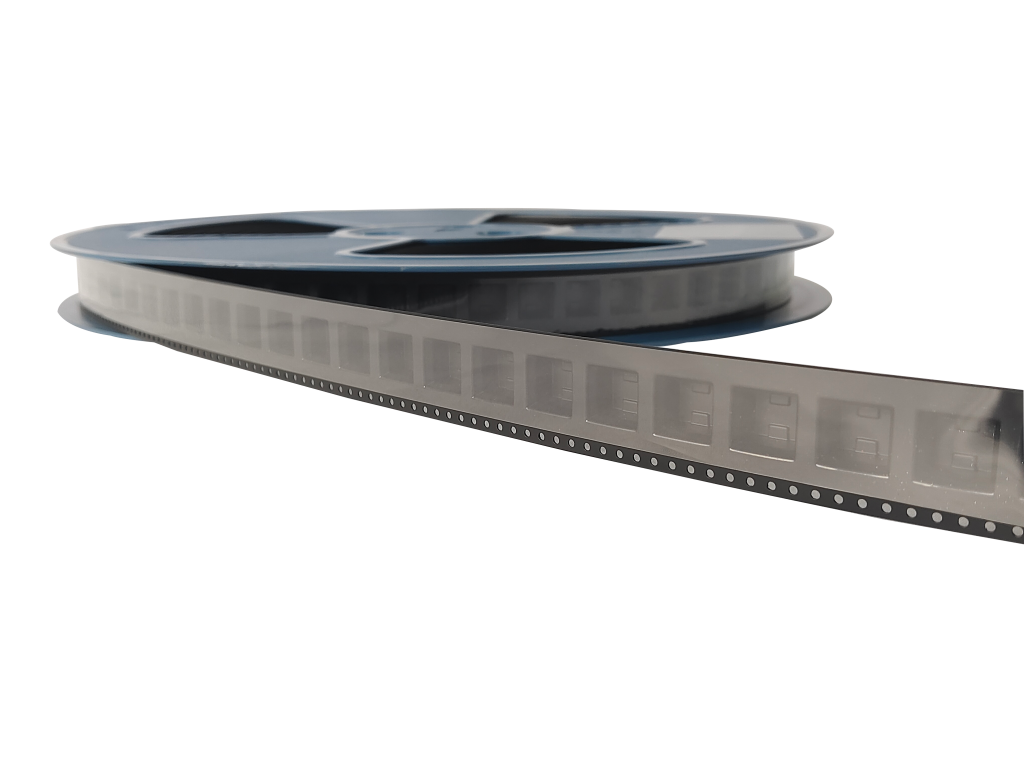

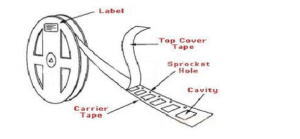

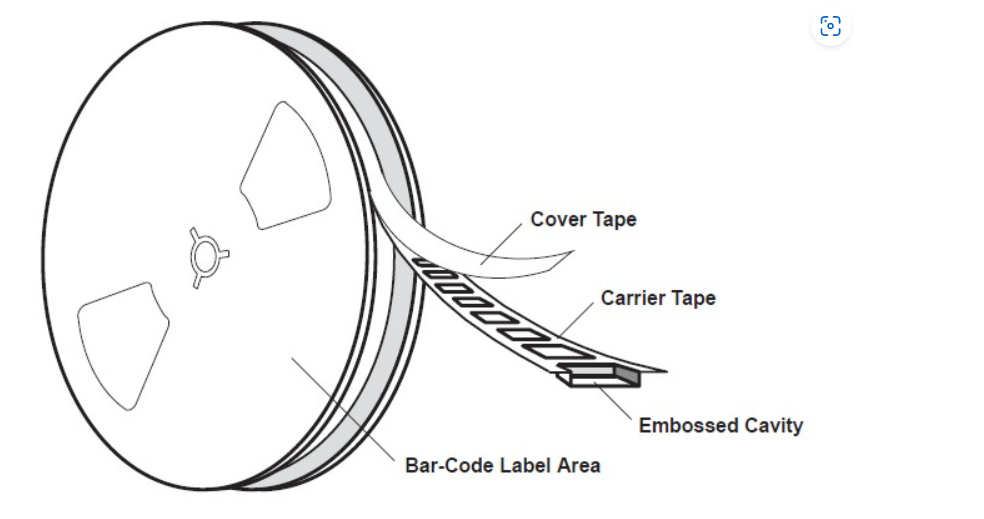

Our latest semiconductor chip packaging material solutions start with carrier tape packaging chips to prevent ultra-thin chips from slipping during the packaging process, and 3M chip packaging material solutions also include the ability to pre-set QR codes that can help customers save time and improve analysis of critical data. In addition, we offer a range of standard and custom cover tapes and precision carrier tapes to ensure maximum yield even for irregular die sizes and pocket shapes.

Chiplet Design – The driver of ultra-small, ultra-thin chips

In less than a decade, pocket sizes for lidding tapes have dramatically decreased. One way manufacturers have responded is through chip design: dividing a single chip into multiple smaller chips to form a “Chiplet” catalog. Manufacturers can “mix and match” these chips into a single package, reducing the need for expensive advanced technology nodes through chip division.

Chiplet integration uses redistribution layers (RDLs), silicon interlayers and substrates associated with advanced packaging, as well as integrated platforms such as 2.5D/3D, fan-out and high-density flip chip designs for new constructions. This also creates a greater challenge for successful chip shipping. So, what is our solution?

A full range of solutions for carrier cover tape

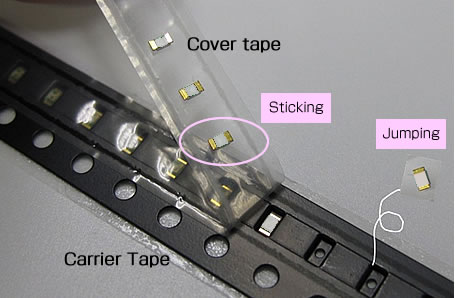

Micro-assembly packaging poses challenges, including problems with chip adsorption and chip slippage during the carrier tape closure process. newwaysmart offers carrier tapes with tolerances as low as 0.02mm and D1 hole sizes as low as 0.01mm. flat bottom surfaces and low die pull angles. Our carrier tapes allow pocket depths to be controlled to less than 0.1 mm. Customized cover tapes help fill ultra-small and irregular gaps and help protect ultra-small components in sizes 0603 and 0402 mm from damage and application problems.

Newwaysmart offers lidding tape solutions for the following component families

Molded plastic, Passive device, WLCSP/bare die, Discrete, LEDs, etc.

Multi-purpose carrier cover tape – semiconductor component carrier cover tape

Newwaysmart offers a full line of insulated and antistatic products that provide precise pocket designs for a wide range of components. We can also customize carrier tapes in order to meet your custom needs.

Carrier tape products to help protect electrical and electronic components during shipping and storage. Our cover tapes offer excellent sealing performance and smooth peel to help ensure efficient extraction and placement operations.The Newwaysmart cover tape line includes tapes with heat sealable cover (HAA) or pressure sensitive cover (PSA).

Advanced semiconductor packaging material solutions with stable yields, sufficient capacity, ultra-low wastage, and reliable quality assurance.Our team of experts has decades of experience in the semiconductor industry and has the technical knowledge to solve the latest process technology problems.