Contact Your NewwaySMTC Representative Now! DuncanLi@newwaysmart.com

What are the main functions of the carrier tape material and the classification of the carrier tape material

Carrier tape material is a very important industrial raw material, especially in the use of electronic components products carrier tape material is very widely used. In addition, we use in our lives, such as cell phones and other daily electronic products have many original parts, carrier tape material is used to carry these electronic raw materials of the packaging class items. In addition to this function, the carrier tape material has many other functions, the carrier tape material here to talk about the function of the carrier tape material, the following we will understand together to download the tape material!

What are the main materials used in the production of carrier tape materials

The production material of the carrier tape material: PS, ABS, PET, PC, HIPS, PE and other plastic materials, special requirements can use metal manufacturing. PC material section is a colorless transparent unqualified thermoplastic material. Its name comes from its internal.

Base teeth. PC chemical properties polycarbonate acid-resistant, oil-resistant, polycarbonate is not resistant to ultraviolet light, not resistant to strong alkali.

Forming method of carrier tape production material

According to the molding method of the pocket, it can be divided into two types of molding, intermittent (flat molding type) and continuous (roller rotation type). Compared with the intermittent type, usually the continuous type molding method has better dimensional stability and higher product dimensional accuracy. For the intermittent molding method, it is more suitable for preparing large size pockets.

The carrier tape material has two main functions, as follows

Carrier tape material selection material and use but very crucial for the molding with carrier tape production. We can use different carrier tape materials according to the customer’s requirements. As an expert in SMD tape manufacturing, we are the best partner for our customers in the consumer electronics manufacturing industry. The function of the carrier tape material is to protect the electronic components and also to protect the interests of our customers.

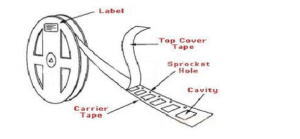

1. The carrier tape material with the use of cover tape, bearing electronic components

Applied to the electronic components SMT plug-in operations, the electronic components are stored in the carrier material packaging, and the carrier material cover tape to form a package to protect the electronic components will not be contaminated and impact. Electronic components in the plug-in operation, the cover tape is ripped open, SMT equipment through the precise positioning of the carrier material positioning holes, the components in the carrier material will be removed in turn, installed on the integrated circuit board to form a complete circuit system.

2. Carrier tape material in order to protect the electronic components from electrostatic damage

Some precision electronic components have clear requirements for the anti-static level of the carrier material, such as in the case of high precision resistance alloy products, the use of carrier material is very much. According to the different anti-static level, the carrier material can be divided into three types: conductive, anti-static (static dissipative) and insulating type.

In addition, the material of carrier tape material mainly includes two types: plastic (polymer) and paper. Embossed carrier material is mainly composed of plastic materials, the mainstream of the market is Polycarbonate polycarbonate carrier material, Polystyrene polystyrene and ABS acrylonitrile-butadiene-styrene copolymer resin carrier material, in addition, there are also a small number of PET, APET and other materials prepared carrier material. Stamped carrier materials are mainly made of paper or PE composites.

Polycarbonate carrier material is characterized by high mechanical strength, good transparency, good dimensional stability, high glass transition temperature and good heat resistance. The mechanical strength of PET is close to that of PC, but because it is a crystalline material, the dimensional stability is poor.