Contact Your NewwaySMTC Representative Now! DuncanLi@newwaysmart.com

The main factors affecting the failure of carrier injection molding

The basis for determining the carrier injection molding is the precision of the injection molded products, i.e. the standard tolerance, form tolerance and appearance roughness of the products. To carry out precision injection molding there are many related conditions necessary, and the Z substance is the plastic material, injection mold, injection molding process and injection molding equipment, which are the four fundamental elements. When planning plastic products, engineering plastic materials should be selected first, and the engineering plastics that can be precision injection molded must be those with high mechanical function, stable standard, good creep resistance, and environmental stress cracking resistance.

Understanding Carrier Injection Molding and the main causes of carrier injection failure

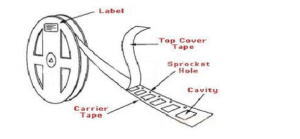

Carrier injection molding. Carrier strip injection molding can also be divided into injection molding molding molding method and die-casting method. Injection molding machine, referred to as injection machine or injection molding machine, is the main molding equipment to make thermoplastic or thermosetting materials into various shapes of plastic products by using plastic molding molds, injection molding is achieved by injection molding machine and molds.

Carrier injection molding is mainly a thermoforming method

Carrier strip injection molding is mostly used for thermoplastics. It is similar to extrusion molding, but the difference is that the molten plastic enters the closed mold through the nozzle, and the product is formed by solidification in the mold. It is used to produce small packaging boxes, daily necessities and shaped parts. The quality of carrier injection molding requires the color, size, structure and appearance of the word mark to be consistent with the integrity, keep clean, packaging protection intact. The most extensive products of injection molding, as long as there is a mold can make products, and it is very convenient.

Affect the causes of carrier injection molding failure should focus on plastic materials and molds

When designing plastic products, engineering plastic materials should be selected first, and the engineering plastics that can be precision injection molded must be those with high mechanical properties, dimensional stability, good creep resistance, and resistance to environmental stress cracking. Secondly, according to the selected plastic material, the finished product dimensional accuracy, piece weight, quality requirements and the expected mold structure, the applicable injection molding machine should be selected. During the processing, the factors affecting the precision injection molded products mainly come from the precision of the mold, injection shrinkage, and the ambient temperature and humidity variation magnitude of the products.

In the carrier injection molding, the mold is one of the keys to obtain the plastic products with the required quality, and the mold for carrier injection molding should effectively meet the requirements of product size, precision and shape. However, even if the accuracy and size of the mold are the same, the actual size of the molded plastic products may not be the same due to the difference in shrinkage. Therefore, it is very important to control the shrinkage rate of plastic products effectively in precision injection molding technology.

Influence the shrinkage rate of plastic for carrier injection molding

The main factors affecting the shrinkage of plastics are thermal shrinkage, phase change shrinkage, orientation shrinkage, compression shrinkage and elastic recovery, which are related to the molding conditions or operating conditions of precision injection molded products.

Therefore, when designing the mold, it is necessary to consider the relationship between these influencing factors and injection conditions and their apparent factors, such as injection pressure and cavity pressure and mold filling speed, injection melt temperature and mold temperature, mold structure and gate form and distribution, as well as the influence of gate cross-sectional area, product wall thickness, the content of reinforcing fillers in plastic materials, the crystallinity and orientation of plastic materials, and other factors. The influence of the above factors also varies depending on the plastic material, other molding conditions such as temperature, humidity, continued crystallization, internal stress after molding, and changes in the injection molding machine. The process of dry injection molding is the transformation of plastic from solid (powder or pellet) to liquid (melt) and then to solid (product). From pellet to melt, and then from melt to product, the middle has to go through the effect of temperature field, stress field, flow field and density field, etc. Under the joint action of these fields, different plastics (thermosetting or thermoplastic, crystalline or non-crystalline, reinforced or non-reinforced, etc.) have different polymer structural forms and rheological properties. All factors affecting the above “field” will definitely affect the physical and mechanical properties, size, shape, precision and appearance of plastic products.

In this way, the intrinsic link between process factors and polymer properties, structural form and plastic products will be expressed through plastic products. The analysis of these intrinsic links is important for the reasonable formulation of the injection molding process, the reasonable design and manufacture of molds according to the drawings, and even the reasonable selection of injection molding equipment. Precision injection molding is different from normal injection molding in terms of injection pressure and injection rate. Precision injection molding often uses high pressure or ultra-high pressure injection and high speed injection to obtain a smaller molding shrinkage.