Contact Your NewwaySMTC Representative Now! DuncanLi@newwaysmart.com

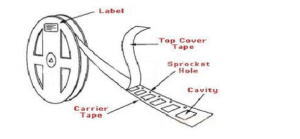

The role of SMD carrier tape punching

The role of SMD carrier tape perforation! When you see SMD carrier tape, have you ever wondered why the SMD carrier tape is perforated? Here newwaysmart to tell you about it!

SMD carrier tape hole punching is the purpose of the SMD carrier hole Due to the shape and other reasons, the packaging will appear after the vacuum, sticky in the patch on the conveyor belt, can not suck the product away, so a hole to discharge. Whether there are products packaged in SMD tape can be ignored. SMD carrier tape can be used to carry electronic components, suitable for the operation of electronic components patch plug-in.

SMD carrier tape is used in the field of electronic packaging tape products. What is the purpose of selecting carrier tape and drilling for SMD?

How to choose the SMD carrier band

After determining the carrier bandwidth subscript, please select the carrier bandwidth according to the size and direction of the device to determine whether the device is antistatic or not, and select the carrier material according to the device type.

Calculate the carrier tape length according to the number of packages and select the SMD carrier band.

Select the tape’s tensile strength, precision, temperature resistance and other performance parameters according to the model and environmental conditions.

SMD carrier tape perforation is the purpose of SMD carrier hole

By the dry shape and other reasons, the packaging will appear straight empty, stick in the SMD carrier tape, can not be sucked away from the product, so a hole to discharge.

SMD carrier tape punching whether there is a product packed in SMD tape can be ignored.

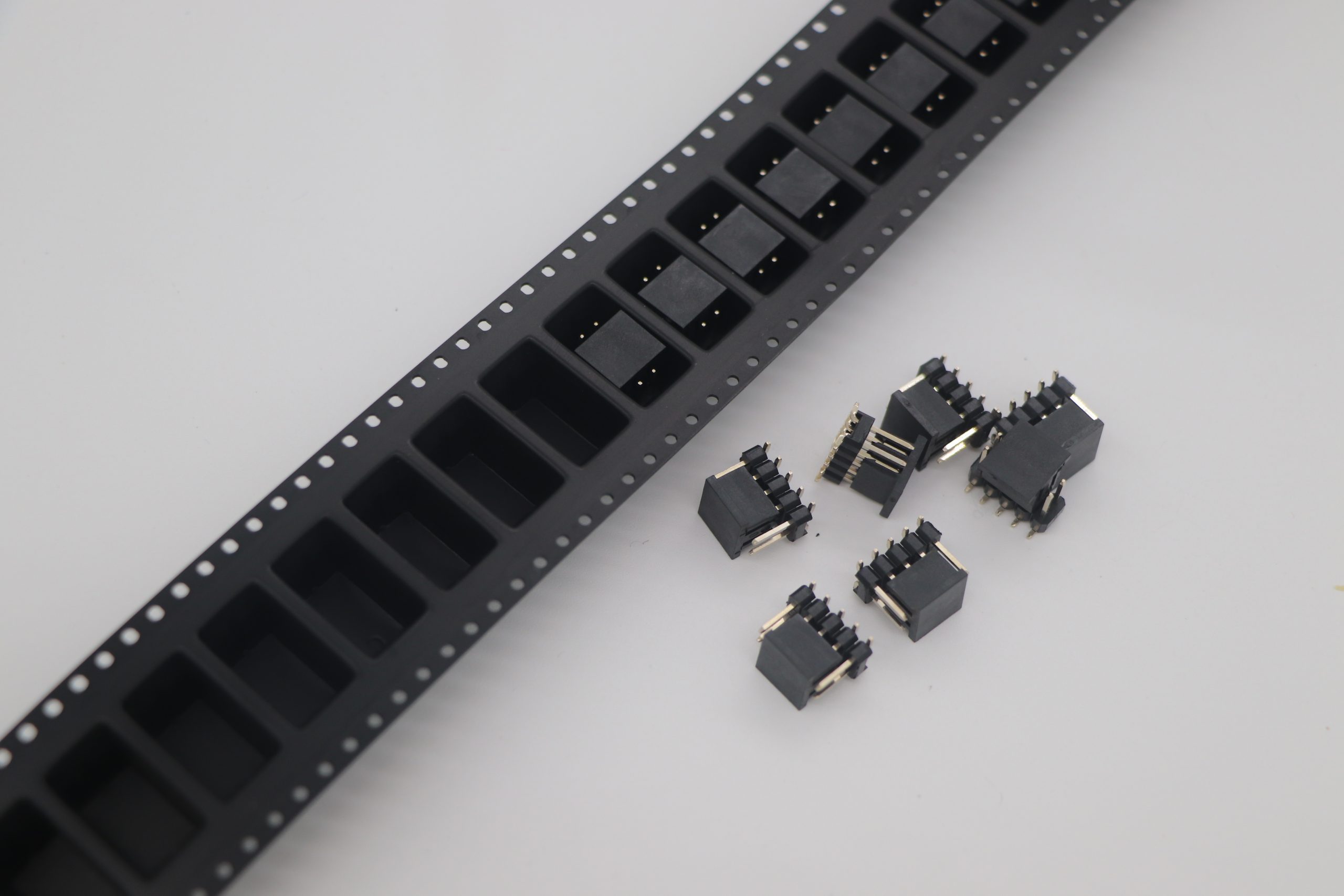

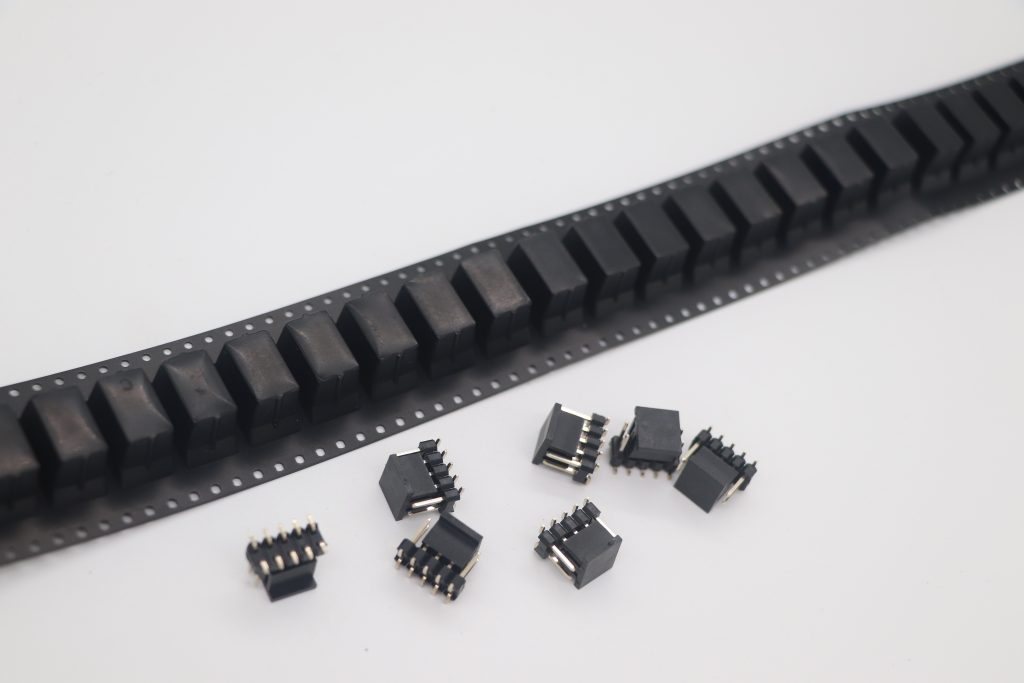

SMD carrier tape can be used to carry electronic components, suitable for the operation of electronic components patch plug-in. Electronic components using the belt and cover to protect the electronic components from pollution and impact. When the electronic components are working, the cover belt is removed and the SMD carrier device takes out the components inside the carrier in turn and pastes them onto the IC board through the positioning holes of the precisely positioned carrier. A complete circulation system is formed.

Anti-static patch carrier can protect electronic components from static damage. Some precision inspection of electronic equipment on the anti-static performance of the patch has clear requirements, SMD carriers according to the level of electrostatic resistance can be divided into conductive, dissipative and insulating

Type, SMD carriers can also be used to protect electronic equipment, SMD carriers with dry encapsulation of integrated circuits to prevent damage to electronic components of integrated circuits in the transmission of the discussion process, the protection of electronic components, the score is also very convenient.

SMD conveyor belt is also easy to carry. SMD conveyor belt is not only easy to carry, but also ensure the productivity of the product, effectively prevent the rate of breakage of the product in the process of transportation, and effectively encapsulate the role of the package.

It is mainly used for the surface mounting of downstream electronic devices. It can be widely used in integrated circuits, resistors, inductors, capacitors, connectors, fuses, switches, relays, connectors, oscillators, transistors and other electronic components. With the downstream electronic component types, sizes and capabilities are continuously upgraded and optimized, the portfolio of SMD carrier systems will continue to evolve and innovate.