Contact Your NewwaySMTC Representative Now! DuncanLi@newwaysmart.com

Cover tape with carrier tape method and process for packaging electronic components

The method and process of cover tape and carrier tape packaging of electronic components is a popular method of encapsulating electronic components, especially surface mount components. The process involves placing the component on carrier tape, which is a continuous strip of plastic with pockets or cavities to hold the component in place. It is then sealed with cover tape, which is usually made of thin plastic film with an adhesive on one side. Cover tapes protect components during shipping and handling and remove components from the carrier tape during assembly.

Cover tape with carrier tape for packaging electronic components

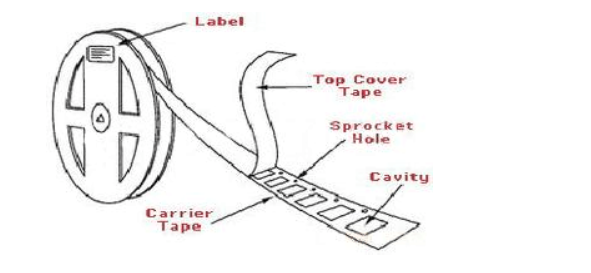

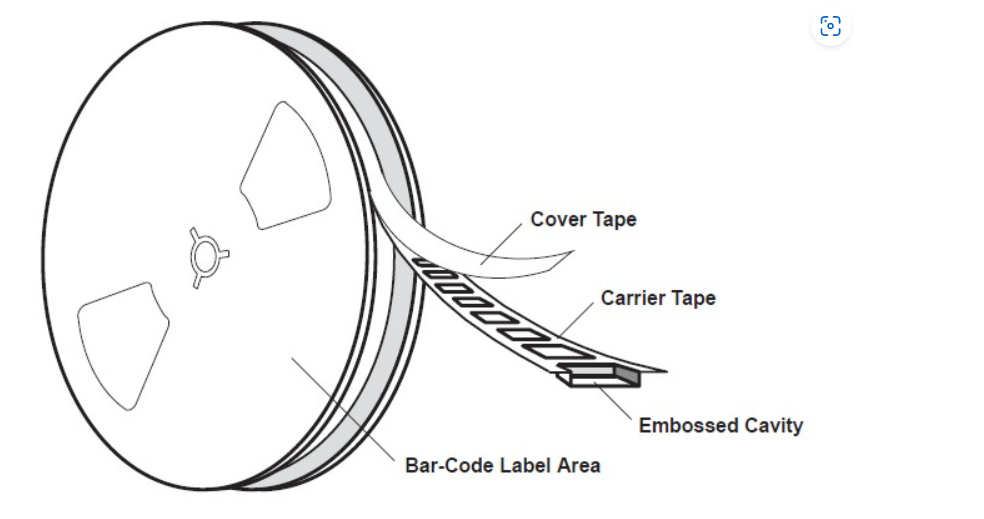

Cover tape with carrier tape is a common method used for packaging electronic components. It involves using two layers of tape to protect and transport the components. The cover tape is a thin, transparent layer that is used to cover the top of the components, while the carrier tape is a thicker layer that provides support and protection for the components during transportation.

Cover tape with carrier tape for the protection of electronic components

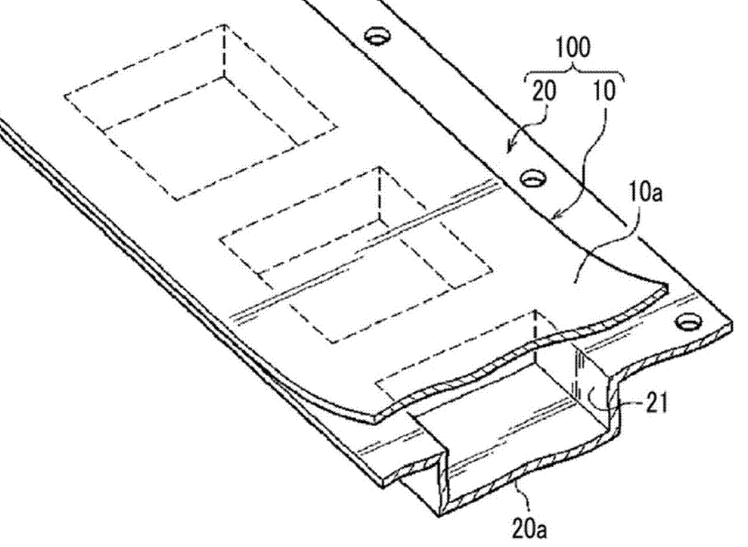

The cover tape is usually made of thin, transparent plastic material, such as polyester or polyethylene terephthalate (PET). It is heat-sealed onto the carrier tape, creating a sealed pocket that protects the components from dust, moisture, and other contaminants. The cover tape also provides a barrier against electrostatic discharge (ESD) which can damage sensitive electronic components.

The carrier tape is made of a thicker plastic material, such as polystyrene or polycarbonate. It has pockets or cavities that hold the electronic components securely in place. The carrier tape is designed to withstand the rigors of transportation, including vibration and impact, while protecting the components inside.

The cover tape and carrier tape are typically wound onto a reel for easy handling and transport. During the assembly process, the components are placed into the pockets of the carrier tape, and the cover tape is then applied over the top, sealing the components inside.

Cover tape with carrier tape is a reliable and cost-effective method for packaging electronic components. It is widely used in the semiconductor industry for the packaging of integrated circuits, surface mount devices, and other electronic components.

Cover tape with carrier tape to package electronic components process

The process for cover tape with carrier tape packaging typically involves the following steps:

1. Component placement: The electronic components are placed onto the pockets or cavities of the carrier tape using automated equipment.

2. Cover tape application: The cover tape is applied over the carrier tape and components using a heat-sealing process or a pressure-sensitive adhesive.

3. Reel winding: The finished carrier tape with cover tape is wound onto a reel, which can hold several thousand components.

4. Inspection: The finished reels are inspected for quality and defects, such as missing components or damaged cover tape.

5. Shipping and storage: The finished reels are shipped to customers or stored until they are needed for assembly.

Cover tape with carrier tape packaging is a highly efficient and cost-effective method for packaging electronic components, especially for high-volume production. It provides secure and protective packaging that can withstand the stresses of shipping and handling.