Contact Your NewwaySMTC Representative Now! [email protected]

Advanced cover tape technology for electronic component packaging

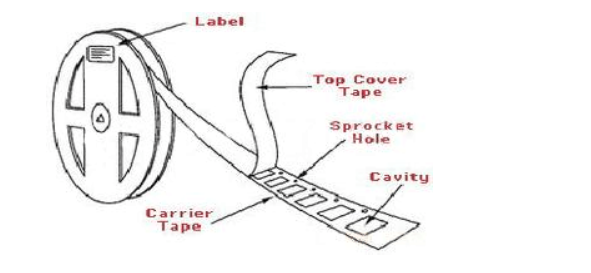

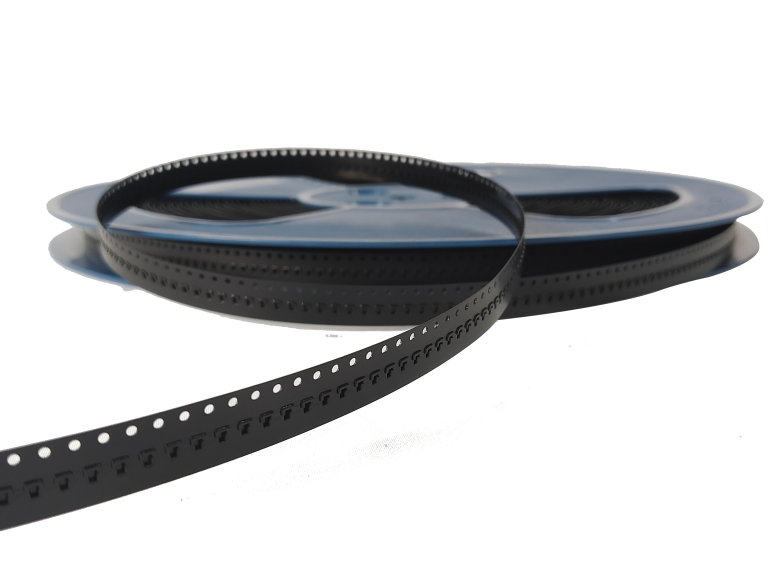

Cover tape is an essential component in the packaging of electronic components such as surface mount devices (SMD) and integrated circuits (ICs). It is used to securely seal the components in their packaging and protect them from environmental factors such as moisture and dust. Advanced cover tape technology has been developed to enhance the performance and reliability of electronic component packaging.

Technical embodiment of the cover tape

The cover tape is an integral part of the packaging process of electronic components, especially surface-mount components. It is a protective tape that is applied to the top of the carrier tape that holds the electronic components, providing protection from external factors such as dust, moisture, and static electricity.

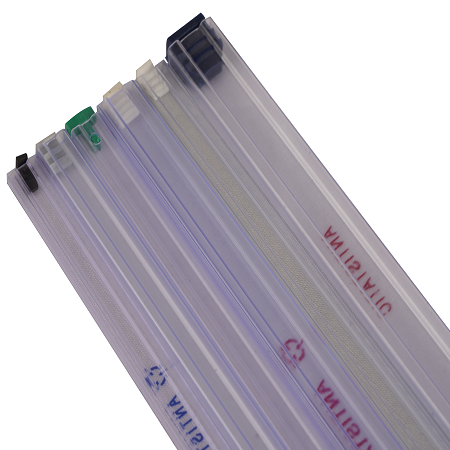

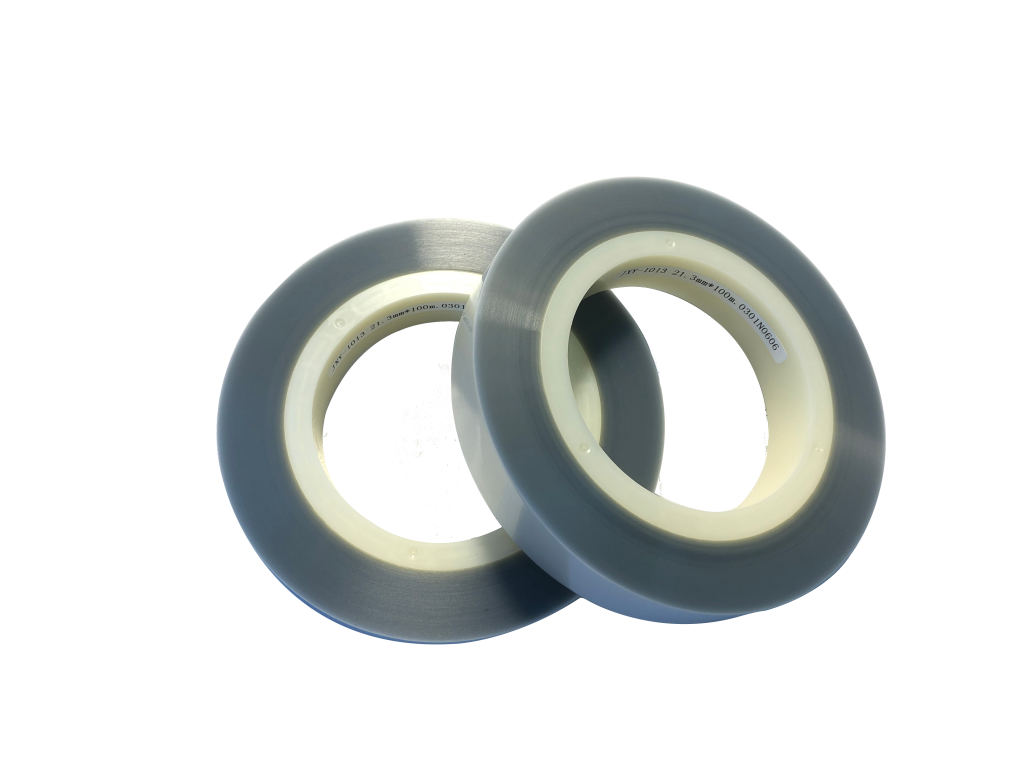

The cover tape is typically made of a thin, flexible, and transparent material such as polyester or polycarbonate. It is coated with an adhesive layer on one side to stick to the top of the carrier tape.

The process of applying the cover tape to the carrier tape is done using a cover tape applicator machine. The machine feeds the cover tape over the carrier tape and uses heat and pressure to bond the adhesive layer of the cover tape to the carrier tape. The machine also cuts the cover tape to the appropriate length, leaving a small strip of the carrier tape exposed at the beginning and end of the tape to allow for pick-and-place machines to remove the electronic components from the carrier tape.

In summary, the technical embodiment of the cover tape involves a thin, flexible, and transparent material coated with an adhesive layer, applied to the top of the carrier tape using a cover tape applicator machine.

There are several advances in the technology of cover tape

One of the major advancements in cover tape technology is the use of antistatic and conductive cover tape materials.

Antistatic cover tapes help prevent static electricity buildup on the surface of the tape, which can damage sensitive electronic components. Conductive cover tapes, on the other hand, provide a shield against electromagnetic interference (EMI) and electrostatic discharge (ESD).

Another innovation in cover tape technology is the use of peelable cover tape, which allows for easy and quick removal of the tape after reflow soldering. This reduces the risk of damage to the components during tape removal and increases the efficiency of the manufacturing process.

In addition, some cover tapes are designed with a high barrier property to prevent the penetration of moisture and other contaminants that can degrade the performance of electronic components. Some cover tapes also come with adhesive that is designed to be more resistant to high temperatures, allowing for reliable sealing even under harsh conditions.

To further enhance the performance of cover tape, some manufacturers have developed cover tape that is compatible with automatic inspection systems. These systems use machine vision technology to detect defects in the packaging process and help identify potential issues before they lead to failures in the field.

Overall, advanced cover tape technology has played a significant role in improving the reliability and durability of electronic component packaging, and is expected to continue to evolve and improve in the future.