Contact Your NewwaySMTC Representative Now! [email protected]

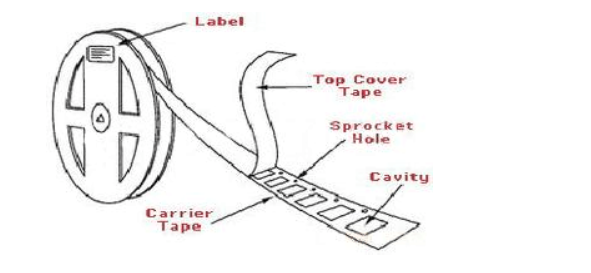

Anti-static carrier tape description and benefits

Anti-static for the carrier tape and electronic packaging is very important, anti-static measures to do good or bad directly affect the effect of the packaging of electronic components, to anti-static carrier tape, ic carrier tape said to add some moisture-absorbing additives is very necessary, mainly to reduce the resistance of the carrier tape and ic carrier tape, this anti-static agent have a very good moisture absorption function, reduce the surface resistance.

What is anti-static carrier tape and the benefits of carrier tape

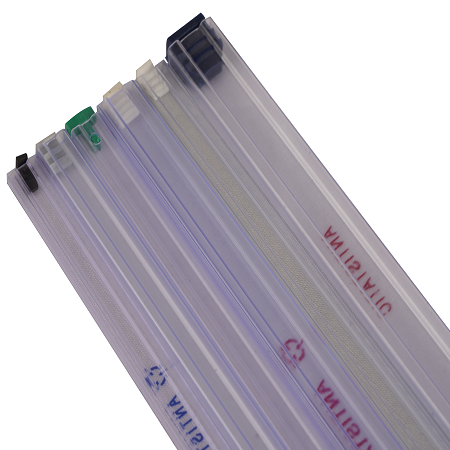

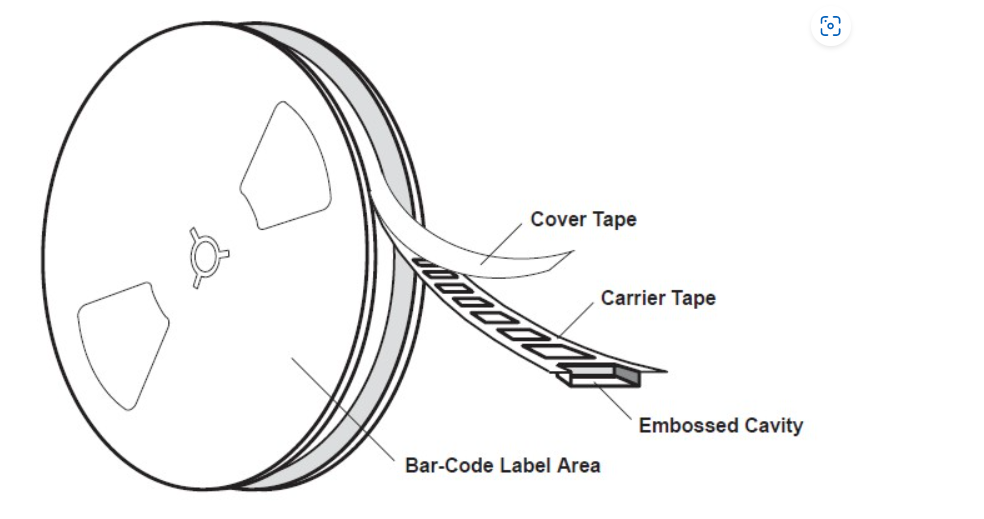

Anti-static carrier tape is a type of tape that is specifically designed for use in electronics manufacturing. It is made from a material that does not produce or retain static electricity, making it suitable for use in the handling and packaging of sensitive electronic components. These tapes are typically made from polyethylene or other conductive materials that can effectively discharge any static buildup that may occur during handling, Anti-static carrier tapes are commonly used in the handling and packaging of sensitive electronic components.

Anti-static carrier tapes are commonly used in the manufacture of printed circuit boards, as well as in the packaging of computer components, memory They are also used in the shipping and storage of these components to prevent damage during transit.

Overall, the use of anti-static carrier tape is critical in ensuring the safe handling, packaging, and transportation of delicate electronic Overall, the use of anti-static carrier tape is critical in ensuring the safe handling, packaging, and transportation of delicate electronic components, and helps to prevent damage and ensure their proper function.

Material of anti-static carrier tape

The main component of anti-static agent is resin, add anti-static carrier tape and IC carrier tape in the production process to play a non-decomposition, non-deterioration, the role of anti-static agent is to absorb moisture in the air, the formation of thin films, play a role in leaking electrons can also increase the smoothness, for quality carrier tape said to do a good job of anti-static carrier tape and IC carrier tape is a very critical thing.

Benefits of anti-static carrier tape

Anti-static carrier tape is a high-temperature thermoforming product, anti-static carrier tape itself undergoes thermal shock and molding. As customers package products and then ship them to different parts of the world, the temperature difference between different parts is different, so the shrinkage and capriciousness of the anti-static carrier tape packaging material at different temperatures is different. So anti-static carrier tape needs to use different formulations in different environments to ensure product stability and to avoid customer complaints caused by the packaging material.

Anti-static carrier tapes provide additional benefits compared to traditional carrier tapes because they have been specifically designed to reduce or eliminate static electricity

The buildup of static electricity can be harmful to sensitive electronic components, as it can cause electrical discharge that can damage or even destroy the component.

The following are some of the benefits of using anti-static carrier tape:

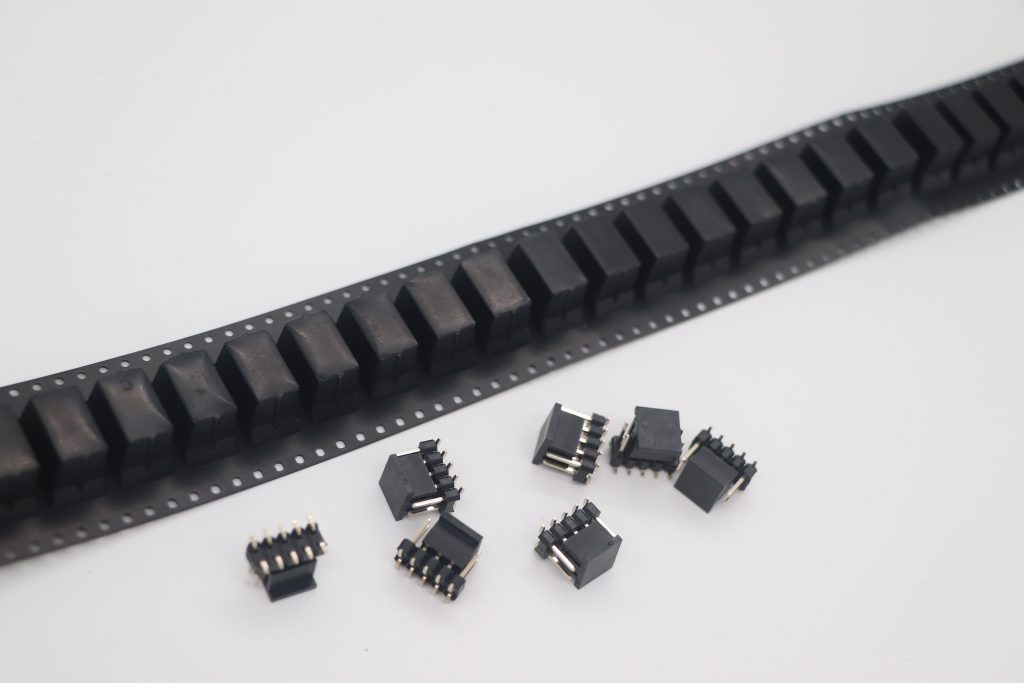

1. Protection against ESD damage: Anti-static carrier tapes prevent the buildup of static electricity, reducing the risk of electrostatic discharge (ESD) damage to electronic components.

2. Improved component reliability: By preventing ESD damage, anti-static carrier tapes can help improve the reliability of electronic components and reduce the number of defective parts in the manufacturing process.

3. Enhanced productivity: The use of anti-static carrier tapes can help increase the efficiency of the manufacturing process, as components are better protected against damage and are less likely to require rework or replacement.

4. Compliance with industry standards: Anti-static carrier tapes can help manufacturers comply with industry standards for electronic component handling and packaging, such as JEDEC J-STD-033, which sets requirements for the handling and packaging of surface-mount devices (SMDs) to prevent ESD damage.

Overall, anti-static carrier tapes offer several benefits that help to improve the reliability and efficiency of the manufacturing process, while also helping to protect sensitive electronic components from damage.