Contact Your NewwaySMTC Representative Now! DuncanLi@newwaysmart.com

Anti-static tape sheet material plays a very important role in the use of electronic components

In the electronics industry, static electricity will adsorb dust and reduce the insulation resistance of electronic components, thus affecting the service life of electronic components. The electrostatic discharge will generate an electromagnetic field or current emitted heat, which leads to interference or damage to electronic components. Static electricity is a major killer of electronic components, static electricity will cause damage to electronic components such as aging. At this point, the anti-static tape sheet material in the protection of electronic components plays a very important role!

What is the role of high-end anti-static for electronic components

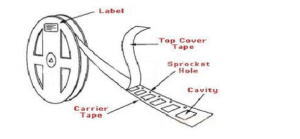

The high-end anti-static carrier tape is an important part of the packaging of precision electronic components and has a very important impact on the automated production and efficiency of electronic components. Anti-static carrier tape needs to use different formulations in different environments to ensure product stability and avoid customer complaints caused by packaging materials. Anti-static products have a conductive function to discharge static electricity.

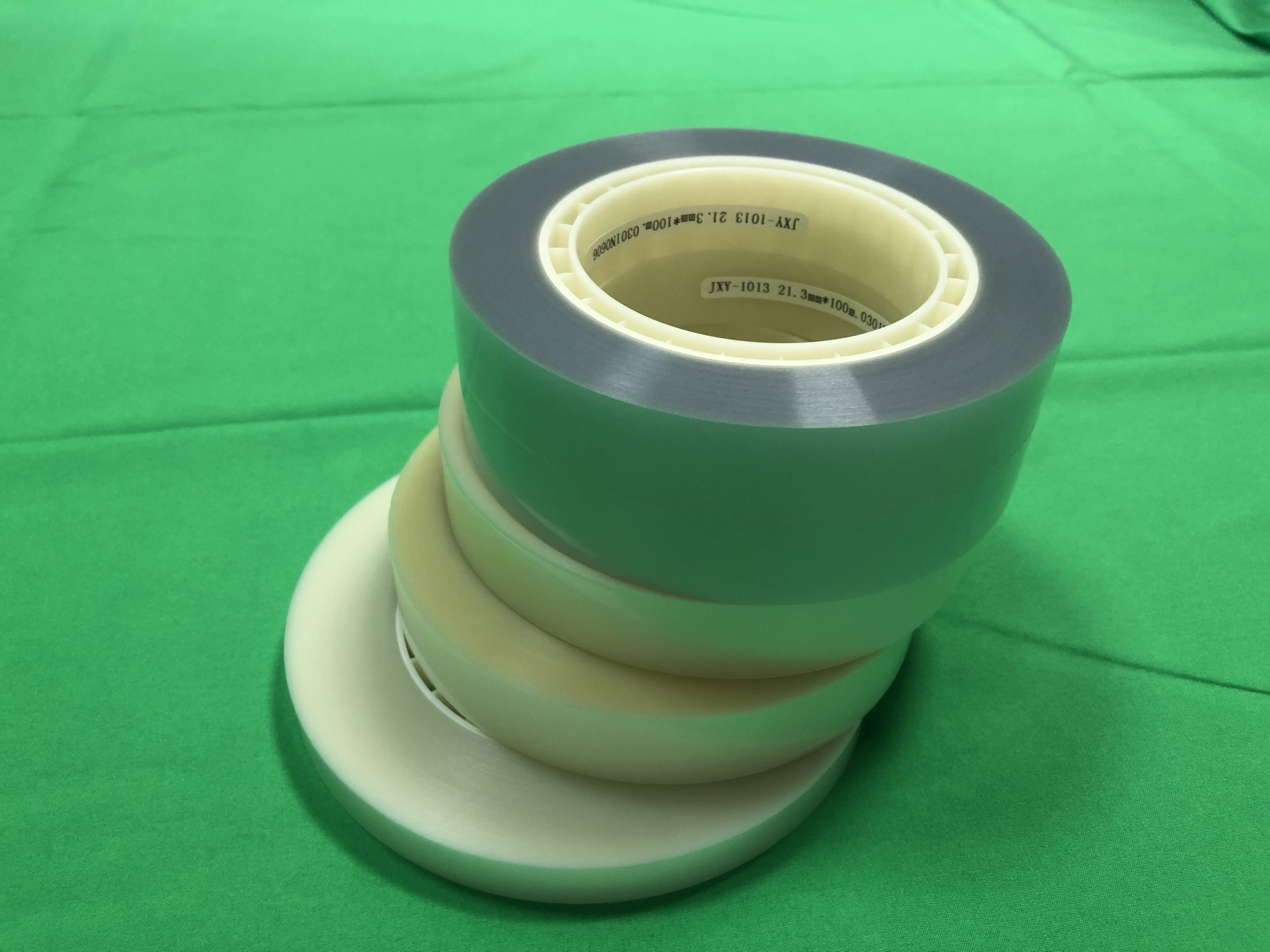

Anti-static top cover tape with a surface resistance of 105 to 1012Ω.

Cover Tape attributes: common type, electrical resistance, color milky white, brown and transparent color, length is divided into 200M/R, 300M/R and 480M/R Cover Tape with due to different manufacturers have a different formula, each has collocation, any manufacturer of cover tape can not arbitrarily with another carrier with collocation, all cover tape and carrier tape must be approved by experiment test before being supplied to customers for collocation use. All materials of Cover Tape must comply with RoHs directive on EU environmental directives of Electronic and Electrical products. The specific standards and related elements with Carrier Tape.

Types of anti-static cover tape

1、Anti-static and high temperature resistant tape.

By using a special production process, the surface static voltage generated in the process of unrolling and peeling is very low, while ordinary polyimide tape in this process may produce more than 10,000 volts of surface static voltage, the surface static voltage may damage the components around it. Therefore, the low static voltage of anti-static high-temperature tape can be very good to eliminate this hazard.

2、Anti-static floor tape.

Color has yellow, black letters, Chinese warning slogans, adhesive for the oil-based special high viscosity rubber glue, specifications: 48MM25M, surface resistance of 107-109 ohms, material: PVC.

3, anti-static adhesive tape.

Anti-static tape is made of anti-electrical materials, with the characteristics of the discharge of electrostatic charge and clear transparency. Use: Applicable to circuit boards, notebook computers, cell phone communications, etc., paste electrostatic sensitive devices processing and bag sealing.

4、Anti-static transparent adhesive tape.

Anti-static index to 10 of 8-10 times, the voltage is less than 50 volts. Used for circuit boards, notebook computers, cell phones and other products that require anti-static external packaging, clean room use.

5, anti-static grid tape.

Is made of anti-electrical materials, with the characteristics of the discharge of electrostatic charge, surface resistance of 10 to the 8th-10th power. Scope of use: applicable to paste electrostatic sensitive devices processing and bag sealing and other electronic products packaging. Specifications: 12MM36M; 18MM36M; 24MM36M; 36MM36M; 48MM36M.

Anti-static tape sheet material in electronic components can be divided into two categories according to their use.

Anti-static type and warning type

Anti-static tape is also divided into two types of grid tape and transparent tape, which itself has anti-static function and can be used for packaging of electronic products.

Anti-static warning tape itself does not have anti-static function, the surface is printed with anti-static logo, can be used for static-sensitive products or anti-static area to play a warning role.

Anti-static tape how to anti-static in electronic components

1. through its surface material for anti-static, the surface is made of anti-static substrate, itself has anti-static function.

2. in addition to its own anti-static role, there is an anti-static warning tape itself does not have anti-static function, the surface is printed with anti-static logo, can be used for static-sensitive products or anti-static area to play a warning role. Anti-static tape is through these two ways of anti-static

Components from the production to the use of the overall process may suffer electrostatic damage, according to the stages of the can be divided into: (1) components manufacturing process; (2) printed circuit board production process; (3) equipment manufacturing process; (4) equipment use process; (5) equipment maintenance process.

In the whole process, each stage in each small step, the components may suffer from the effects of static electricity, and in fact, the most important and easy to neglect the point is in the process of transmission and transport of components. In this whole process, not only the packaging is prone to static electricity due to movement, and the entire package is easily exposed to the external electric field (such as through the vicinity of high-voltage equipment, workers move frequently, vehicles move quickly, etc.) and damaged, so the transmission and transportation process requires special attention to reduce losses and avoid unnecessary disputes.