Contact Your NewwaySMTC Representative Now! [email protected]

Benefits of Carrier Tape and Cover Tape

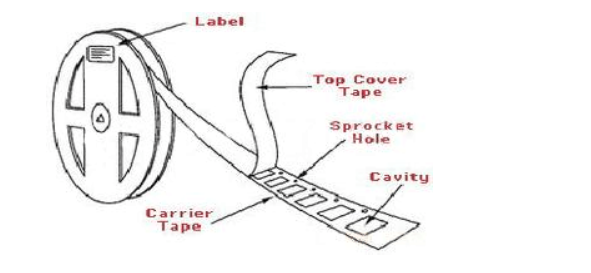

Cover tape is a tape product used in the field of electronic packaging, in conjunction with a carrier tape.

Basic introduction to cover tapes and carrier tapes

The cover tape is usually made of polyester or polypropylene film as the base layer, and laminated or coated with different functional layers (antistatic layer, adhesive layer, etc.), which can be sealed on the surface of the carrier tape under external force or heating to form a closed space to protect the electronic components in the carrier tape pocket. The carrier tape has a specific thickness, in the direction of its length is equally spaced distribution of holes for electronic components (also known as pockets) and positioning holes for index positioning.

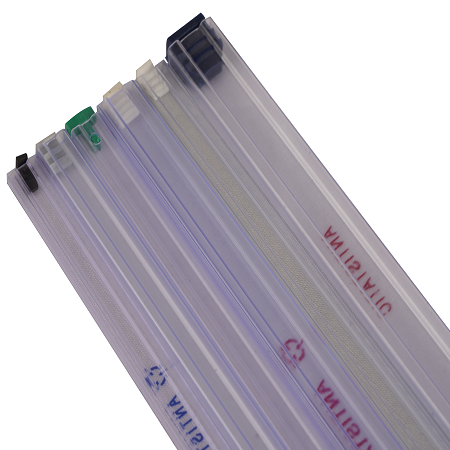

Types of antistatic cover tapes and carrier tapes

They are to protect the electronic components from electrostatic damage, some precision electronic components on the carrier tape anti-static level has clear requirements. According to the anti-static level, the carrier tape can be divided into three types: conductive, anti-static (static dissipative) and insulating. So the two are complementary to each other, in order to better protect the accessories inside.

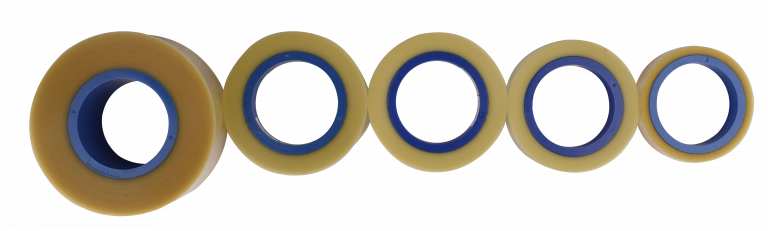

Cover tape and carrier tape under heat-sensitive action

According to the characteristics of the cover tape and carrier tape adhesion and peeling from the carrier tape, the cover tape can be divided into three types, thermal cover tape (HAA), pressure sensitive cover tape (PSA), and the new universal cover tape (UCT).

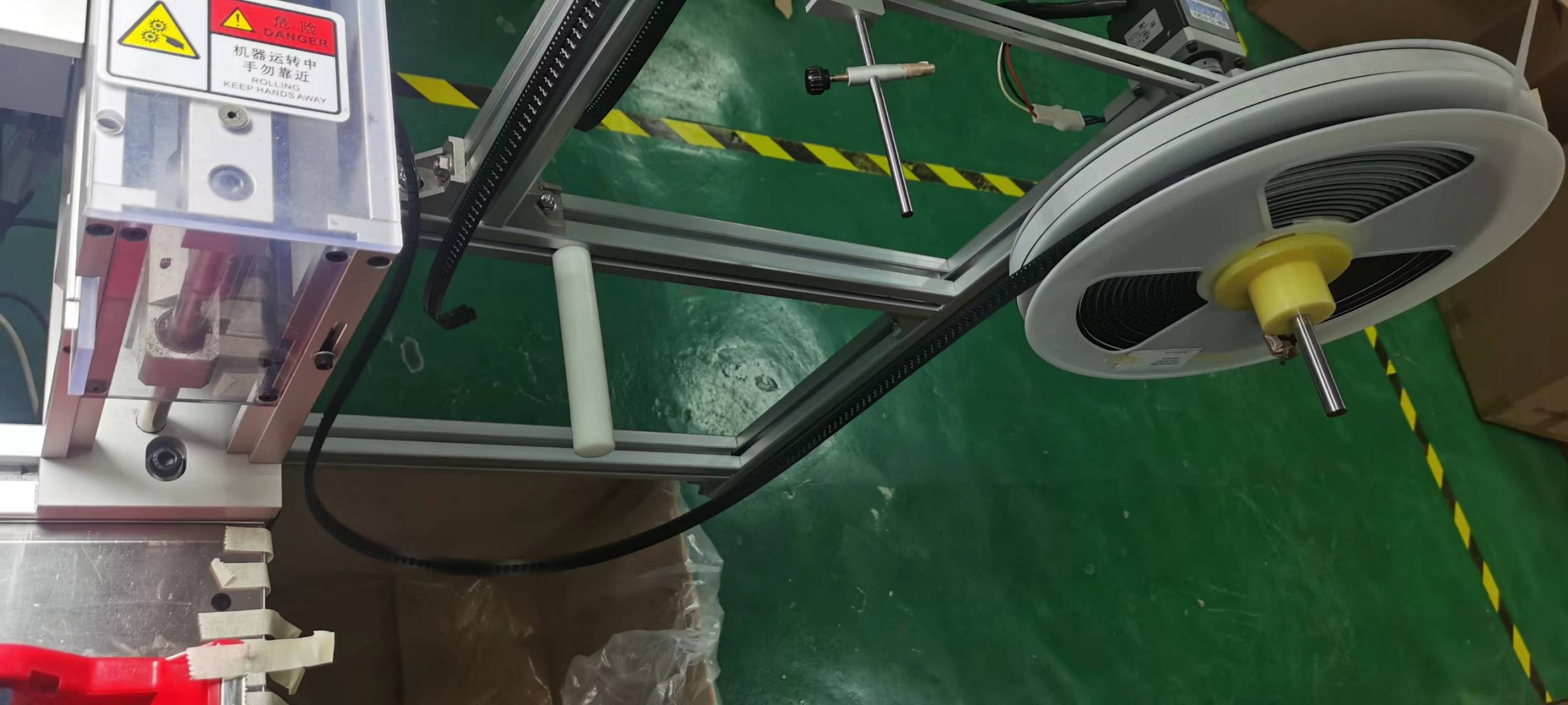

Thermal cover tape (HAA)

The sealing of the thermal cover tape is done by the sealing machine by applying a certain temperature and pressure through the sealing presser foot, so that the hot melt adhesive of the cover tape melts and presses on the sealing surface of the carrier tape to achieve sealing. Thermal cover tape is not sticky at room temperature, but sticky after heating.

Pressure-sensitive cover tape (PSA)

The sealing of pressure-sensitive cover tapes is done by a sealing machine that applies continuous pressure through a pressure roller to bond the pressure-sensitive adhesive of the cover tape to the carrier tape. The two sides of the pressure-sensitive cover tape are adhesive at room temperature and can be used without heating.

New Universal Cover Tapes (UCT)

The cover tape on the market mainly through the adhesive force to control the size of the peeling force, but because of the same adhesive with different surface materials of the carrier tape when the size of the adhesive force will be different, and the adhesive force in different temperature environments and aging conditions will also change, coupled with the peeling sometimes appear residual adhesive pollution, to solve these specific problems, the market has introduced a new universal cover tape, which no longer Instead of relying on the adhesive force to control the peeling force, two deep grooves are cut in the base film of the cover tape through precise mechanical processing, and the cover tape is torn along the grooves when peeling. In addition, only the middle part of the cover tape is peeled off when peeling, while the two sides of the cover tape are still bonded to the sealing line of the carrier tape, so it also effectively reduces the pollution of equipment and components by residual glue and debris.

The above shows the benefits of the cover tape and the carrier tape itself, which are self-contained and beneficial to the electronic component customer base.