Contact Your NewwaySMTC Representative Now! [email protected]

Case of carrier tape and cover tape sealing cracking

The problem of cracked carrier tape seal is mainly caused by the mismatch between the carrier tape and the cover tape, and the different material formulation technology used in the production of carrier tape by different manufacturers, etc. To solve the problem of cracked carrier tape seal, we need to carry out two kinds of product testing and other testing measures.

Why is there a problem in the sealing of the carrier tape and the cover tape?

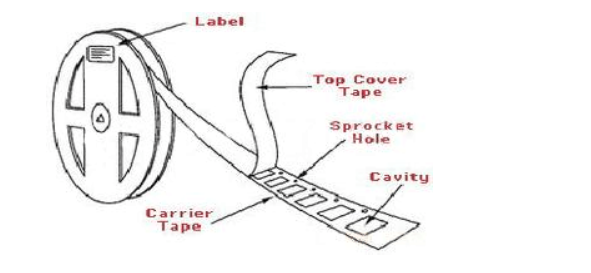

Carrier tape and cover tape sealing. The basic packaging function of electronic packaging is realized. However, as a package for SMD electronic components, it also assumes a function that cannot be replaced by other common packages.

The function of the carrier tape affects the limitations of the package

Such as anti-static function, personalized packaging function, carrier transport function, etc.. To meet these functions, this brings many restrictions to the materials used in the manufacture of these two products, and also creates many problems. For example, the title says “Carrier tape sealing cracking problem”. However, this problem is not inevitable. As long as the right method, the use of the correct, can fully meet the SMD electronic packaging function, but also safe to use, no worries.

The problem of matching carrier tape and cover tape in raw materials can affect the problem of sealing and cracking

Customers are satisfied with the use of peace of mind. Carrier tape sealing cracking problem, in the final analysis is the carrier tape and the upper cover tape mismatch caused. Let’s start with the basic materials of these two products. The general raw material of the carrier tape is PC, PS, ABS, etc. The material of the carrier tape is not compatible with the material of the upper tape due to different chemical composition or different melting points. Naturally not easy to adhere, or produce too tight and too loose. It will form a bonding peel too light or too heavy, and cannot adapt to the requirements of the upper tape peel. To meet the upper tape and carrier tape compatible with the match, and to achieve a certain effect, it is necessary to infiltrate chemical additives in the manufacture of the cover tape, or to combine with some chemical compounds.

Manufacturers can also influence the problem of carrier tape and cover tape cracking in the seal

Due to the different producers of carrier tape materials, when producing carrier tape materials, due to their different formulas, combined with a variety of substances, adding conductive particles and other habits or preferences, with a certain type of upper tape bonding, there will be different results. Therefore, we always emphasize that different top tapes should not be bonded with any kind of carrier tape. Moreover, the components to be packaged are different, and the strength to be peeled off after bonding is different. We cannot say the same thing. The only way to find out is to experiment with them. Find out the specifications of the two compatible products and find out the suitable sealing conditions.

How to solve the problem of cracking of carrier tape and cover tape seal?

The carrier tape seal cracking problem, in the end, is the carrier tape and the cover tape mismatch. Let’s start with the basic materials of these two products. The general raw material of the carrier tape is PC, PS, ABS, etc. The material of the carrier tape is not compatible with the material of the upper tape due to different chemical composition or different melting points. Naturally not easy to adhere, or produce too tight and too loose. It will form a bonding peel too light or too heavy, and cannot adapt to the requirements of the upper tape peel. To meet the cover tape and carrier tape compatible with the match, and to achieve a certain effect, it is necessary to infiltrate chemical additives in the manufacture of the cover tape, or combined with certain chemical materials.

So, to solve the problem of carrier tape sealing and cracking. It is necessary to ensure that the two products are tested, and after simulating different external environments and conditions, aging tests are conducted at different times. And to ensure that the tested compatible top cover tape and download tape are single and the sealing condition is fixed.