Contact Your NewwaySMTC Representative Now! DuncanLi@newwaysmart.com

Causes of SMD carrier tape E value is small brought about by the reasons

We all know that to stabilize SMD carrier tape appears E value is very useful, not only for our SM on the quality of the production of the carrier tape, but also for customers to get our products to use with confidence a crucial reason.

SMD carrier tape E value is small what is the reason

SMD carrier tape in the production and commissioning process, often encounter the problem of E value is small, many people do not know the causes of E value is small, after analysis and summary, the main reasons for the E value of the carrier tape is small, come together to understand it!

First, the position of the punching die is not in place, which is the most likely to occur in the production of the tape bad condition. If the punching die is misaligned, that is, the punching die and the guide are not in a straight line, it will easily lead to the small E value of the carrier tape; if the punching die position is too far back, it is not attached to the punching die, and the punching needle hits the edge of the carrier tape, it will also easily lead to the small E value of the carrier tape. Therefore, the position of the punching die should be grasped in place.

Second, in the case that the die blade is not slotted, the change of the die blade position or the change of the needle fixing plate will cause the process can not be adjusted, which will lead to the small E value.

Third, the side indenter crushes the raw material edge, causing the raw material side to protrude, when the raw material into the die after the protruding position will make the raw material can not be close to the die, resulting in a small E value of the carrier tape.

Fourth, the carrier tape shrinkage or raw material bending and other undesirable phenomena may also lead to the carrier tape E value is small.

Fifth, if there is debris into the die guide slot, making the die guide slot position bruising, this will also easily lead to the strip E value is small.

Why will lead to SMD carrier E value is small

In the case that the SMD carrier tape is not given on the punching die head, the change of direction of the punching die head or the change of the fixed immovable plate of the punching needle are not adjustable in the processing process, thus causing the E value to be small.

Safety hazards of SMD carrier tape in the production process can lead to small E values

SMD carrier tape shrinkage or material bump and other safety hazards are also very likely to cause SMD carrier tape E value is small.

Residues and waste on the stamping die of SMD carrier tape can lead to low E value

If there is waste into the stamping die guide slot, prompting the stamping die guide slot direction knock, or stamping die residue. That will also easily cause SMD carrier tape E value is small.

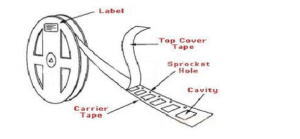

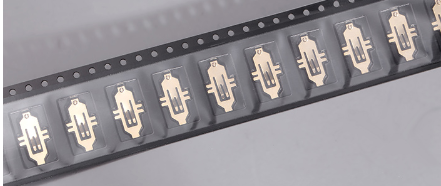

SMD carrier tape as part of the packaging of electronic parts, in addition, must also be the rubber tray and the upper tape of the mutual cooperation of the division of duties in order to carry out the packaging of electronic parts. SMD carrier tape is the main character of automation technology in the whole process of packaging, but without the mutual cooperation of the upper tape and rubber disk is also empty. SMD carrier tape bears the weight of electronic parts to ensure the precision of the electronic parts and maintenance without injury, the upper tape is to carry out the sealing posture of SMD carrier tape, to avoid electronic parts.

The upper tape is to carry out the sealing posture of the SMD carrier to avoid the electronic parts from falling easily from the SMD carrier, and the rubber tray undertakes to carry out the preparation posture of the SMD carrier with good sealing. And in the automated technology production line with each other smt placement machine application. Since the creation and invention of SMD carrier tape so far we have been.

For how to reduce the application of human resources, how to speed up the manufacturing rate, to supply a large number of electronic equipment and strive.

Anti-static is very critical for SMD carrier tape and electronic packaging

The effectiveness of antistatic countermeasures will immediately jeopardize the actual effect of the packaging of electronic components. For antistatic SMD carrier tape and icSMD carrier tape, it is necessary to add some preservatives with moisture absorption effect, mainly to reduce the resistor of SMD carrier tape and icSMD carrier tape. This type of antistatic agent possesses very good moisture absorption and reduces the surface resistance. The main component of antistatic agents is epoxy resin. Antistatic SMD carrier tape and ICSMD carrier tape in the process is not easy to dissolve or poisonous change, antistatic agent effect is to digest the absorption of water in the air, produce plastic film, leakage of electronic devices, enhance the smoothness. Get the antistatic SMD carrier tape and IC chip SMD carrier tape in the work of the SMD carrier tape is very critical, but also to stabilize the SMD carrier tape E value is vital.

In summary, in the SMD carrier production process, you need to pay attention to the above issues, in order to better avoid the problem of small E value of the carrier tape, to ensure the quality of our carrier production and stable production output.