Contact Your NewwaySMTC Representative Now! DuncanLi@newwaysmart.com

Design and processing of packaging carrier tape for micro resistors

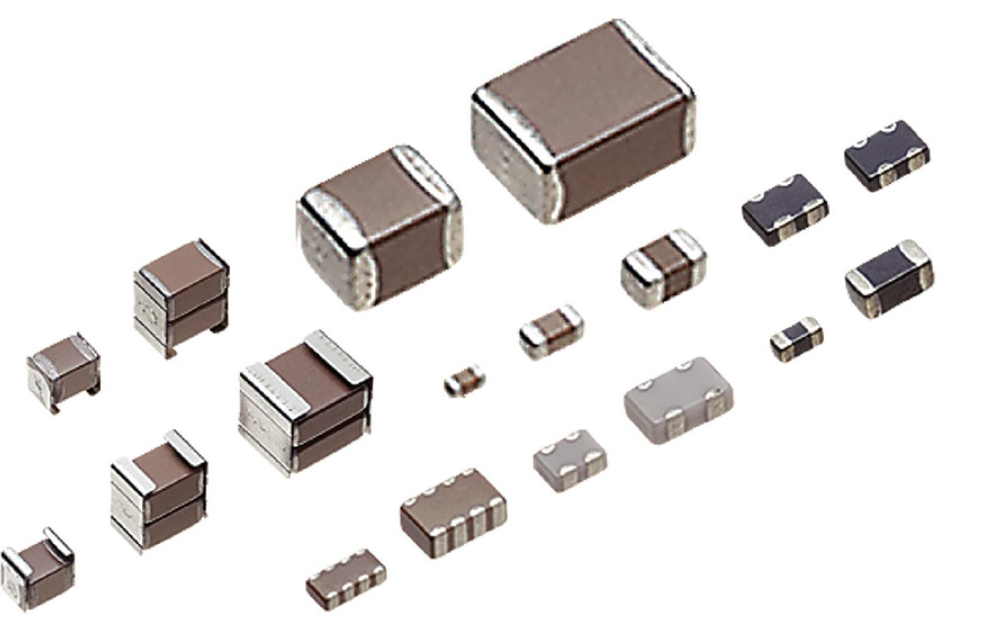

Micro resistors are mainly used to change the resistance value by changing the length of the resistor into the circuit. For resistors that are sensitive to temperature, the resistance value can also be changed by changing the temperature, which is called thermistor. There are also light-sensitive resistors, by changing the intensity of light to change the resistance of the purpose, which is called light-sensitive resistors. In addition, there are also pressure sensitive resistors, air sensitive resistors, etc.

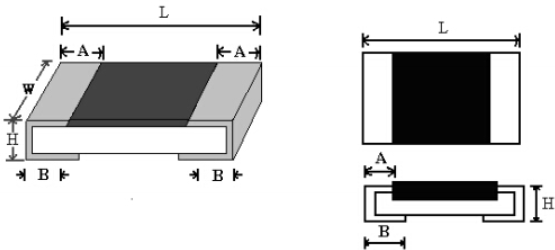

Model selection and product details of micro resistors

Micro resistors can be divided into many different models and types according to the size of the resistance value, production process, production materials, the range of adjustment, the form of adjustment, size, etc. They are divided into: chip adjustable resistors, electronic components adjustable resistors, porcelain disc adjustable resistors, wirewound adjustable resistors, etc.

Common micro resistors and related parameters details

1. Micro resistors RM065C-V2

Performance:

Resistance range (Ohms): 100~2M

Residual resistance: R≤ 1KΩ :30Ω MAX ,

R>1KΩ:3%MAX

Rotation life: R≤15% max. for 100cycles

Resistance deviation: R<500KΩ:±20% ,R≥500Ω:±30%

Resistance variation characteristics: B

Higher use voltage: AC50V

Rated power: 0.1W

Mechanical characteristics:

Rotation angle: 220°±20°

Rotating torque: 80~150gf.cm

Stopping strength: 0.5Kgf.cm MAX

2. Micro resistor RM065C-H2

Performance:

Resistance range (Ohms): 100~2M

Residual resistance value: R≤ 1KΩ :30Ω MAX ,

R>1KΩ:3%MAX

Rotation life: R≤15% max. for 100cycles

Resistance deviation: R<500KΩ:±20%, R≥500Ω:±30%

Resistance variation characteristics: B

Higher use voltage: AC50V

Rated power: 0.1W

Mechanical characteristics:

Rotation angle: 220°±20°

Rotating torque: 80~150gf.cm

Stopping strength: 0.5Kgf.cm MAX

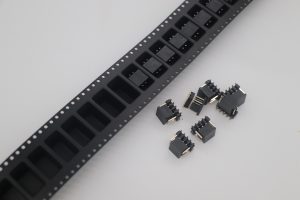

The structure of micro resistor and its role in the carrier tape

Micro resistors consist of a body and a rolling or sliding system. Its working principle is similar to potentiometer. According to the data can be divided into carbon film type, wire-wound type and solid core type trimming resistors. For this reason, micro resistors are widely used in electronic devices for volume control in receivers and audio. Because of the small and delicate nature of micro resistors, the SMT packaging method used in the market is also more common. Carrier tape packaging can better protect micro resistors from damage. Therefore, the market demand for carrier tape packaging is becoming more and more common.

Benefits of using carrier tape packaging for micro resistors

The customer requires a suitable packaging method to be developed, and all we have to do is to take the required material and design the carrier tape to fit the package size. The circuit of the miniature resistor is mounted, connected, fixed, potted, and marked according to the specific input and output of the process technology, we design the carrier tape is to meet the customer is needed to better protect the miniature resistor.

Benefits of carrier tape for packaging micro resistors

Carrier tape can be used in the electronic device packaging industry strip goods, micro resistor packaging carrier tape design should be installed product specifications designed to fit the loading hole. The tape has a special thickness, with the main bone (also known as the bag) for holding the micro resistors and the precise positioning holes for accurate positioning of the database index at regular intervals in its length and orientation. What items must be tested in the quality inspection of the carrier tape, length, width, height, perspective, diameter, depth, hole position, arc and other dimensions and its carrier tape each bag of high precision specifications.

a) Protection: the carrier tape has the protection of the circuit working environment and the outside world isolation, with moisture, dust.

b) Support: carrier tape can lead end and shell in the assembly and welding process to maintain the distance and buffer stress role.

c) Heat dissipation: carrier tape packaging can make the circuit work when the heat exerted.

d) Electrical insulation: carrier tape packaging to safeguard against electrical interference with other components or circuit units.

e) Transition: the conversion of the physical dimensions of the carrier tape packaging circuit.

We have a variety of conventional general components of ready-made molds, and according to the workpiece samples provided by customers to design the applicable carrier tape, the size of fine, in line with the EIA-481 guidelines; can be processed to form a variety of carrier tape, there are ordinary type and antistatic type, according to the customer’s product design mold, our carrier tape molding machine can do depth up to 35MM, carrier tape molding process has been accumulated over the years has been quite mature, the production of The quality of the products produced can fully meet customer requirements.