Contact Your NewwaySMTC Representative Now! [email protected]

Heat sealing and Auto-adhesion Cover Tapes to improve the efficiency of products

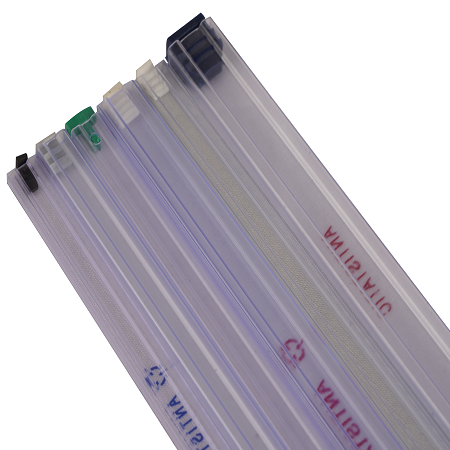

SMT transparent material and transparent SMT electronic packaging cover tape

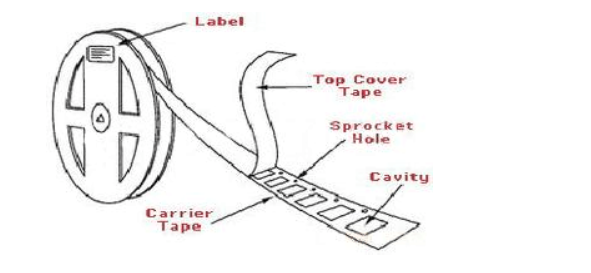

The cover tape includes heat sealing cover tape and auto-adhesive cover tapes are mainly used in the electronic component mounting industry.

It is used together with carrier tape (carrier tape), which will resistor, capacitor, transistor, diode, and other electronic components in the pocket of the carrier tape, and the cover tape is sealed above the pocket formed by the carrier tape to form a closed packaging, which is used to protect the electronic components from contamination and damage during transportation. When the electronic components are installed, the cover tape is stripped, and the automatic installation equipment, through the precise positioning of the index hole of the carrier tape, takes out the components put in the pocket in order and installs them on the integrated circuit board (PCB board).

Heat sealing and Auto-adhesion Cover Tapes standard

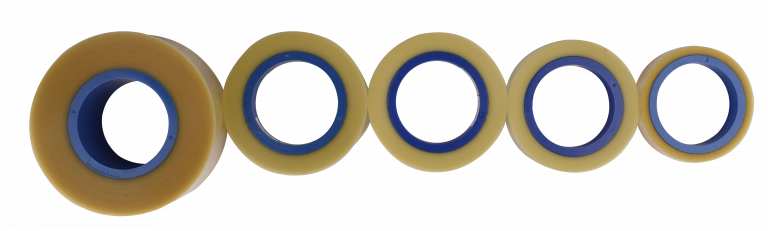

Depending on the width of the matching carrier tape, the cover tape is also divided into different widths. The common widths are 5.3 mm (5.4 mm), 9.3 mm, 13.3 mm, 21.3 mm, 25.5 mm, 37.5 mm, etc.

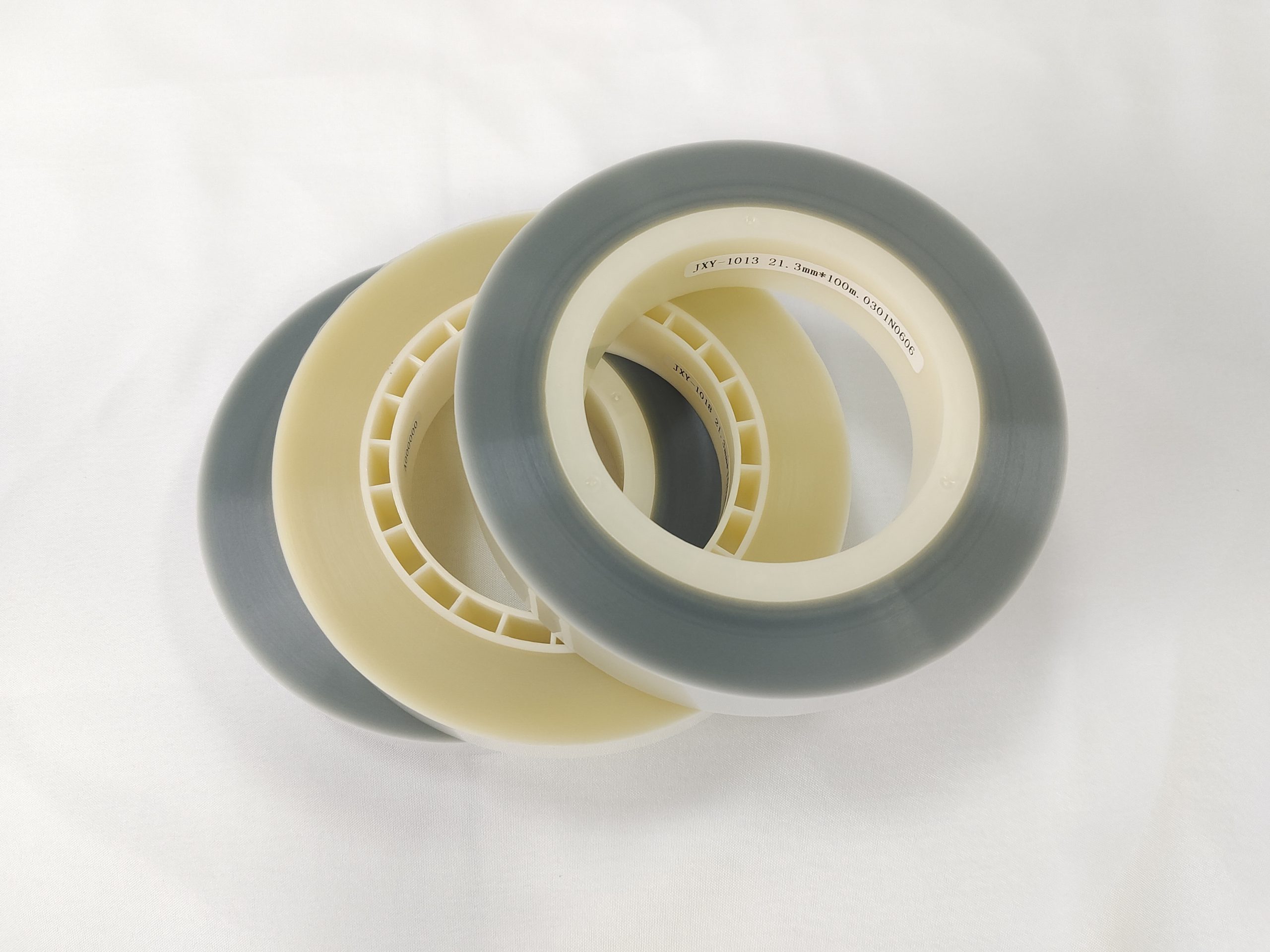

Our commonly used Cover tape is heat activated when heat and pressure are applied. Heat sealable cover tape requires heating in the sealing equipment for bonding. The lengths of these tapes are generally 300M/R and 480M/R; the appearance is transparent and milky white and teal. Auto-adhesive lidding tape does not need to be heated in the sealing equipment, because the material has a pressure-sensitive material, when sealing with pressure, it can be automatically sealed. The length of this type of lidding tape is only 200M/R. The appearance is transparent and brown.

Heat sealing and Auto-adhesion Cover Tapes material

According to the electrical properties of the material, the top cover tape can be divided into three types: anti-static type, conductive type, and insulating type. Conductive top cover with a surface resistance value of 104 ~ 106Ω; because of the low resistance value, anti-static products with conductive function can discharge static electricity. Anti-static upper cover with a surface resistance value of 105 ~ 1012Ω; insulated upper cover with a surface resistance value of 1012Ω or more. Easy to generate static electricity and can not discharge itself. Top cover tape properties: ordinary type, anti-electrical, colors: cream, teal, and transparent, lengths: 200M/R, 300M/R, and 480M/R. Top cover tape due to different manufacturers’ formulations, each match, any manufacturer’s top cover tape can not be arbitrarily matched with another’s carrier tape, all the upper and lower tape sealing must be approved by the test, before matching supply to customers.

All the materials used in the top cover tape must comply with the EU environmental protection directive for electrical and electronic products ROHS, and the specific element standards are the same as those for the carrier tape.

The cover tape has become an important part of the current electronic components and is used together with the carrier tape to form a perfect packaging for electronic components, which plays a protective role for electronic components. In the current market, cover tape has been adapted to the high efficiency, high speed, and miniaturization requirements of modern electronic products.