Contact Your NewwaySMTC Representative Now! [email protected]

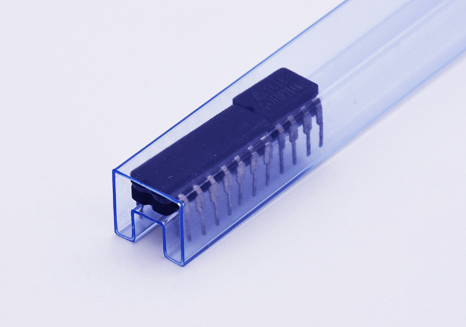

IC packaging tubes are suitable for electronic components

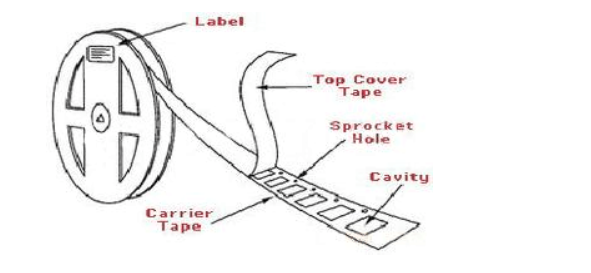

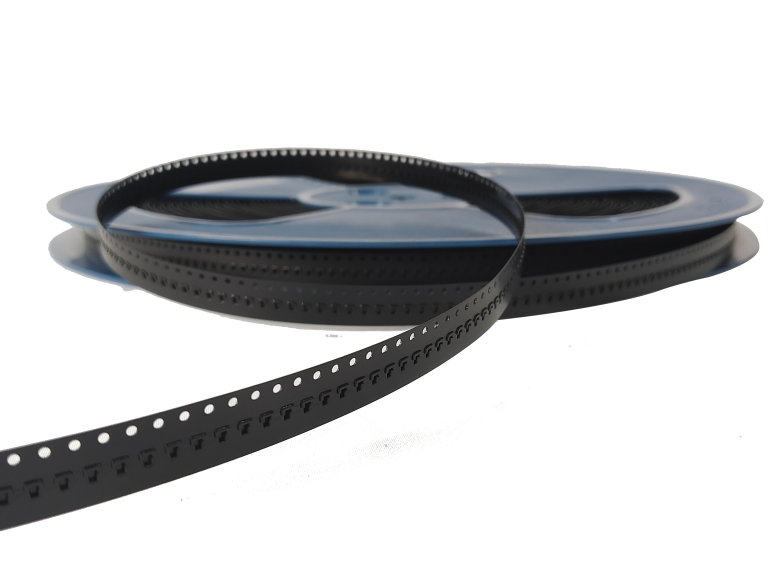

Integrated Circuit (IC) packaging tubes are used for packaging electronic components, specifically IC chips, which are used in various electronic devices such as computers, smartphones, and other digital devices. The packaging tube serves as a protective enclosure for the IC chip during the manufacturing process and transportation.

Advantages of IC packaging tube features

Integrated circuit (IC) packaging tubes are used to protect and transport ICs during the manufacturing process, shipping, and handling. Some advantages of using IC packaging tubes include:

1. Protection: IC packaging tubes provide protection to ICs from physical damage, electrostatic discharge (ESD), and other environmental factors. The tube is made of materials that shield the IC from potential hazards, ensuring that the IC remains safe and functional.

2. Organization: IC packaging tubes are typically labeled with part numbers and other identifying information. This makes it easy for manufacturers to keep track of different ICs, ensuring that the right components are used in the right products. Additionally, the tubes can be stored in racks or trays, making them easy to access and transport.

3. Efficiency: IC packaging tubes are designed for automated handling and assembly. This means that the ICs can be quickly and efficiently loaded into automated equipment, reducing manual labor costs and increasing production speed.

4. Cost-effective: IC packaging tubes are often reusable and recyclable, making them a cost-effective solution for manufacturers. Additionally, they are lightweight and compact, which reduces shipping costs and storage space requirements.

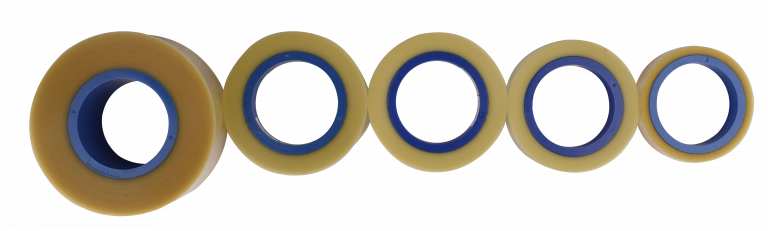

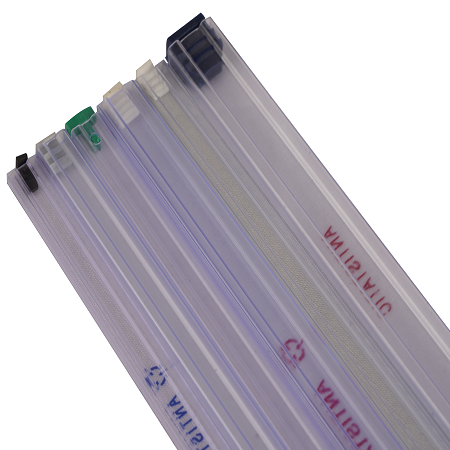

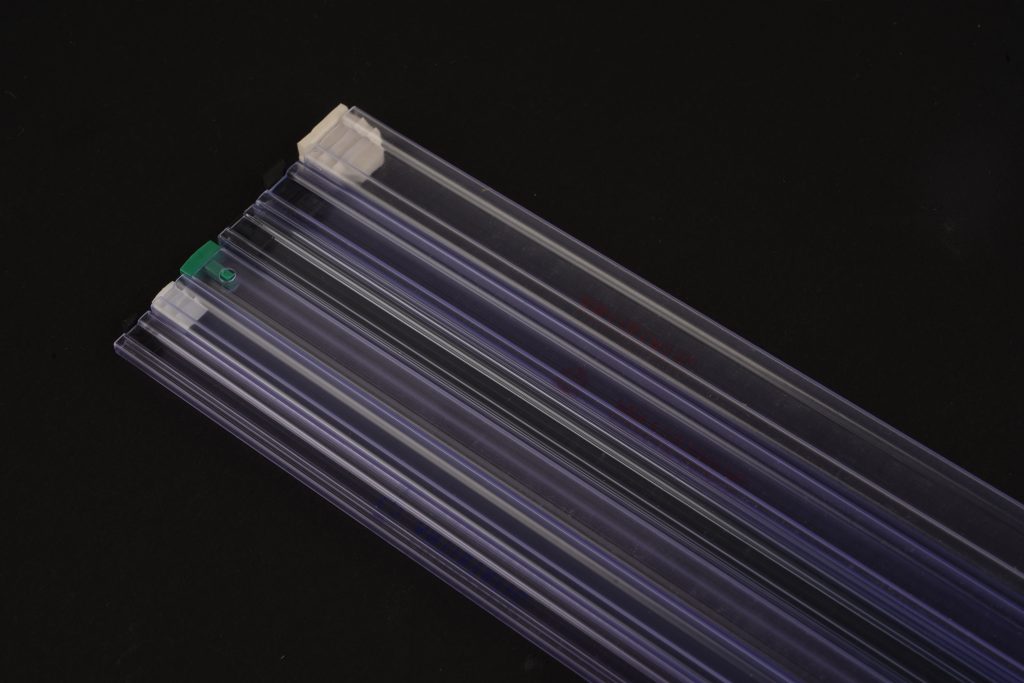

5. Versatility: IC packaging tubes are available in a wide range of sizes and configurations to accommodate different IC sizes and types. This makes them a versatile solution for manufacturers who work with a variety of ICs.

IC packaging tubes provide a reliable and efficient way to protect and transport ICs during manufacturing and shipping, making them an essential component of the electronics industry.

IC packaging tubes play an important role in the packaging of electronic components

IC packaging tubes (also known as IC shipping tubes or carrier tubes) are widely used in the semiconductor and electronics industry to package and transport a variety of electronic components, including integrated circuits (ICs), diodes, capacitors, and resistors.

IC packaging tubes are suitable for electronic components

The IC packaging tube is usually made of plastic or other materials such as polycarbonate, polyethylene, or ABS. These materials are lightweight, durable, and have good chemical resistance, making them suitable for use in the manufacturing and transportation of electronic components.

The packaging tube is designed to securely hold the IC chip and prevent it from moving during transport. It also protects the chip from dust, moisture, and other environmental factors that may damage or affect its performance. The tube also has an antistatic property that helps to prevent the buildup of static electricity, which can damage electronic components.

IC packaging tubes come in different sizes and shapes depending on the size and shape of the IC chip they are meant to hold. They are typically used in high-volume production environments, where electronic components are manufactured in large quantities.

In summary, IC packaging tubes play a crucial role in the packaging of electronic components, providing a secure, durable, and protective enclosure for IC chips during manufacturing and transportation.