Contact Your NewwaySMTC Representative Now! DuncanLi@newwaysmart.com

Increasing demand for chip carriers in the market

With the development of the electronics market, the trend of smaller and smaller chips, the carrier tape has also developed in the direction of precision accordingly.

Carrier tape precision market description

Generally 8-24mm wide bandwidth only has positioning holes on one side, more than 24mm wide carrier tape has positioning holes on both sides, so the width of the carrier tape is different, and the precision is all different, usually the larger the carrier tape, the larger the tolerance allowed. Then the chip application brings the carrier tape development is very promising.

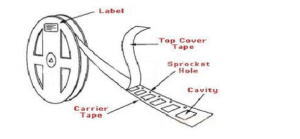

Chip carrier tape is a tape product used in the field of electronic packaging, which has a specific thickness and has holes for placing electronic components and positioning holes for indexing distributed equidistantly along its length.

Chip carrier tape is mainly used in the electronic component placement industry, where it is used together with cover tapes to place electronic components such as resistors, capacitors, transistors, diodes, etc. These components are stored in pockets in the carrier tape and form a closed package by sealing the cover tape above the carrier tape, which helps to protect the electronic components from contamination and damage during transportation.

Depending on the size of the electronic components to be carried in the package, the carrier tape is also divided into different widths. Common widths include 8mm, 12mm, 16mm, 24mm, 32mm, 44m, 56mm, 88mm, etc. With the rapid development of today’s electronics industry, modern enterprises to produce smaller, more sophisticated electronic products will be an inevitable trend, the chip will also be more sophisticated, smaller, as an indispensable downstream industry in the electronics industry – carrier tape, will also follow the development trend of electronic components and changes, corresponding to the direction of precision development.

What are the functions of carrier tape?

The main function of carrier tape one

Electronic components can be carried by the cover of carrier tape. Applied to the SMT plug-in operation of electronic components, the electronic components are stored in the carrier tape packaging, and the tape covered by the carrier tape forms a package to protect the electronic components from contamination and influence. When the electronic components are inserted, the cover tape is torn off and the SMT equipment removes the components from the carrier tape through the precise positioning of the carrier tape positioning holes and installs them on the integrated circuit board to form a complete circuit system.

Carrier tape main function two

Carrier tape can protect electronic components from electrostatic damage. Some precision electronic components have clear requirements for the anti-static level of the carrier tape. According to the anti-static grade, carrier tape can be divided into three types: conductive, anti-static and insulating.

Carrier tape serves for the chip to be correctly placed in the slot. The carrier tape is the support body for the chip and the lead for the chip to be connected to the surrounding circuit. In recent years, the demand for chip carrier tapes has continued to grow rapidly due to the massive demand and development of chips.