Contact Your NewwaySMTC Representative Now! [email protected]

Installation and application of carrier tape on SMT machine

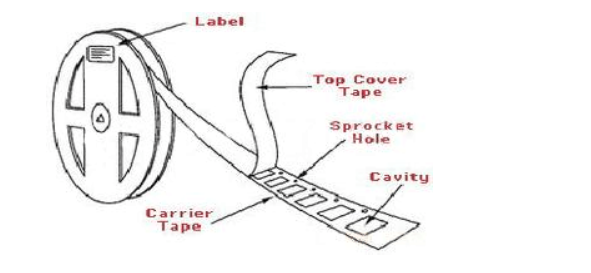

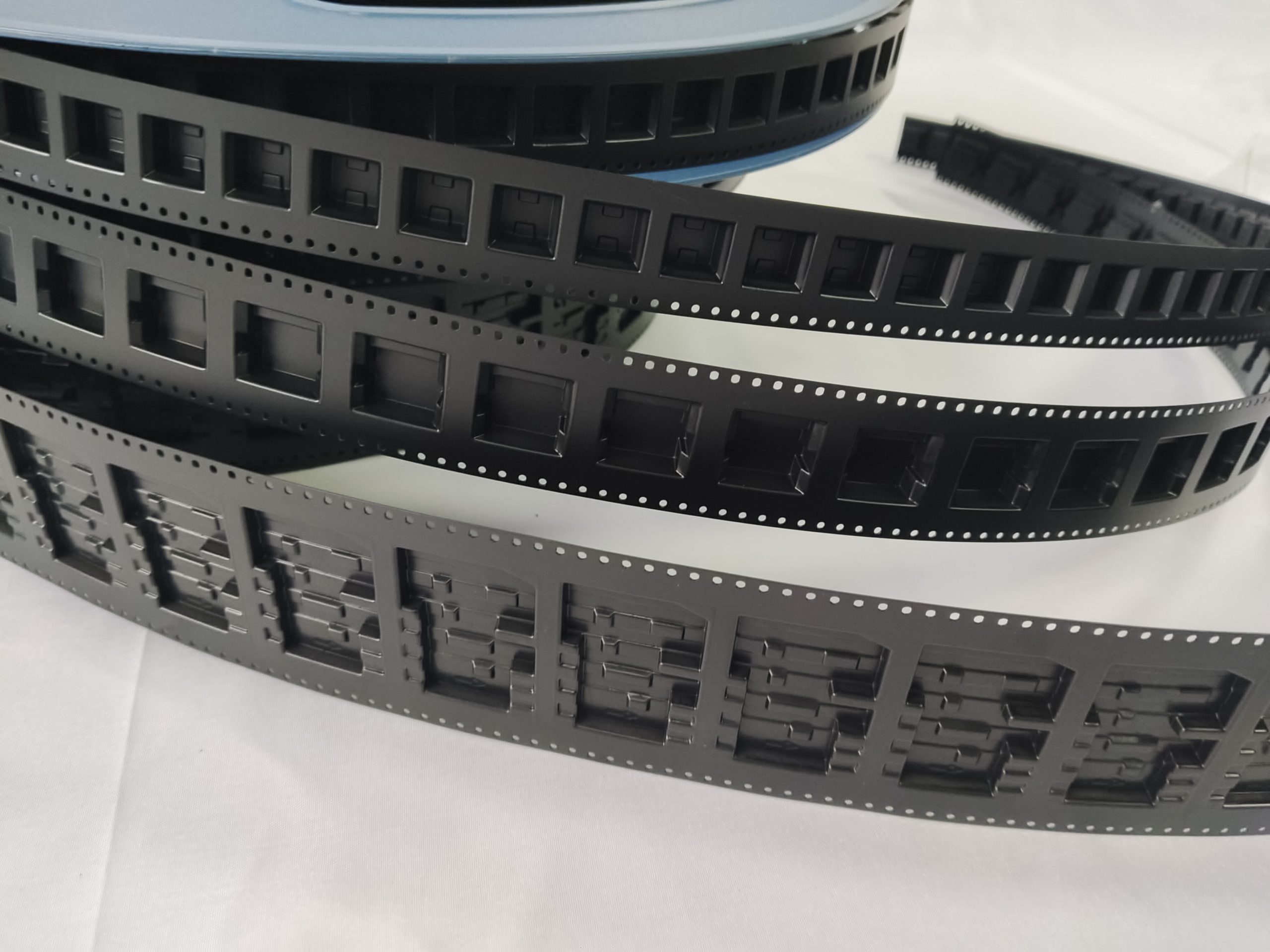

The development of SMT installation process has promoted the industrialization of chip components, while the small size and multifunctional requirements of people for cell phones, computers, home appliances and other electronic products have promoted the development of chip components in the direction of high integration and miniaturization. Electronic components thin carrier tape is developed with the promotion of chip components, which can realize the fully automatic, high-efficiency, high-reliability and low-cost installation requirements of chip components packaging link, and become an indispensable consumable in its production process.

The installation and application of carrier tape on SMT machine

Carrier tape as electronic components SMT mounting process important carrier and consumables, on the one hand to realize the basic function of electronic packaging, on the other hand also bears many other subsidiary functions, such as anti-static, personalized packaging, bearing transport, etc. Therefore, thin carrier tape plays an important basic role in the whole surface mounting process, and its product quality directly determines the packaging performance of electronic components.

How to install and apply the carrier tape

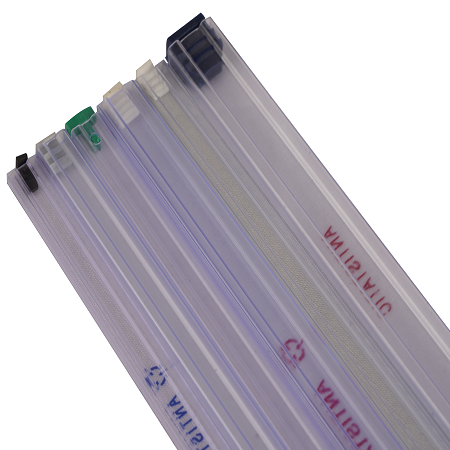

Electronic components are widely used in surface mount, consume a large amount, and have rich varieties and specifications. The basic electronic components, including IC chips, resistors, inductors, capacitors, diodes, etc.

Carrier tape installation in SMT

Normally, the carrier tape and carrier tape plastic rolls are mounted on the SMT, and after debugging, the SMT station process is automatically adjusted and the SMT machine can be used to form a complete electronic component circuit system. The use of SMT equipment can quickly increase the yield of carrier tape.

Carrier tape in SMT equipment applications

The use of SMT equipment can form a complete circuit system for fully automated, high-efficiency, low-cost mounting of chip electronic components. Due to the high degree of automation, SMT equipment can even replace new plastic rolls of carrier tape by itself, eliminating the need for manual board changes.