Contact Your NewwaySMTC Representative Now! [email protected]

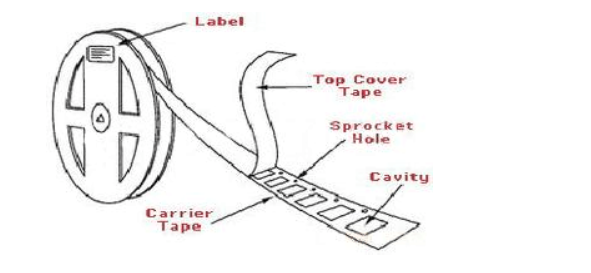

Packaging tube for electronic components

Newwaysmart focus on the design, production and sales of high quality IC packaging tube, the company has a good R & D design capabilities, the products produced are widely used in packaging, electronics industry and other fields, and the products are sold around the world, with integrity, strength and product quality recognized by the industry. Switch packaging tube, professional protection of your electronic components products.

What are the products and features of the company’s packaging tubes for electronic components?

We focus on customizing non-jam packaging tubes for component manufacturers, and we have been deeply involved in IC packaging tubes for more than 18 years, providing solutions for your automated production line pipeline packaging.

The company’s main packaging tubes for electronic components

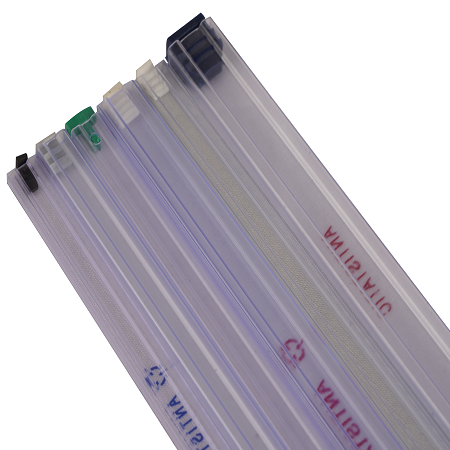

Our main products are: IC packaging tube, LED packaging tube, connector packaging tube, electronic components packaging tube, transformer packaging tube, switch packaging tube, motor packaging tube, power module packaging tube, relay packaging tube, PVC packaging tube, material tube, packaging tube, blister tube, vacuum tube, transparent packaging tube, packaging square tube, PS packaging tube, etc.

Features of packaging tubes for electronic components

Newwaysmart switch packaging tube has the characteristics of accurate size, anti-static, not easy to jam material, no impurities, no thorns, high transparency, good elasticity, high wear resistance, product pressure resistance, strong fall resistance, high toughness, not easy to deformation, easy to bond, hard texture, good anti-dry performance, strong corrosion resistance, low fluid resistance, high mechanical strength, good water tightness, durable, easy to install, etc. The product is more suitable for Automatic production line use.

How to do customization of electronic component packaging?

First of all, our customers will need to customize the drawings of electronic components packaging tube or customer’s product samples in kind to provide to us. We perform CDA accurate simulation design, and finally test and customize the packaging effect of the material tube.

The process of customizing electronic components packaging tube

1. Communicate with customers about their needs

2. Provide drawings

3. We confirm the drawing

4.Mold making

5.First sample confirmation

6.Mass production

7.Finished product inspection

8. Packaging and shipping

Choose us to customize electronic components packaging tube

1.We have senior R & D experience, support customization, provide diversified R & D design solutions for customers

2. Environmentally friendly and transparent, our custom-made plastic packaging tubes have reasonable design, stable production process and good dimensional accuracy control, thus more suitable for automatic assembly line packaging and not easy to jam.

3. Good transparency of electronic components packaging tube, no burrs, no spots, easy for production line staff to quality check the good or bad parts packaging.

As a deep plumber of custom electronic components packaging, we can customize the material, specification and sealing method. Customize the IC packaging tube to meet your needs. We are not only a provider of packaging tubes for electronic components, but also a provider of pipeline packaging solutions for automated production lines.