Contact Your NewwaySMTC Representative Now! [email protected]

Plastic carrier tape domestic industry status

Want to become a high-quality domestic plastic carrier tape company, we must recognize their advantages and their positioning in the market, understanding the industry’s industry status is very important, the so-called know your enemy, a hundred battles will be won.

Plastic carrier tape market concentration is low, the competitiveness of the leading foreign level compared to a large gap

China’s SMD plastic loading industry started late, compared to the world’s leading level of Japan, Taiwan and the United States, the concentration of enterprises is low, and technology lags behind. After China became the electronic information manufacturing base, the international carrier tape production giant 3M, Taiwan carrier tape manufacturers have set up manufacturing plants in China and occupy a high market share, and we need to learn from them. In the multi-level nature of electronic information manufacturing products for local SMD plastic loading enterprises to create a certain amount of production space, most of China’s plastic carrier tape production enterprises for small-scale, inexpensive product suppliers, 2012 above-scale national plastic packaging boxes and containers manufacturing enterprises only 1450, excluding unrelated enterprises, the scale of the larger SMD plastic loading enterprises are few, the main domestic industry consists of Small manufacturers, the concentration is very low, failure to effectively integrate resources, the industry competitiveness needs to be improved, the face of foreign competitors have a higher possibility of losing market share.

Plastic carrier tape overall R & D strength backward, high-end materials rely on imports, profitability is adversely affected

SMD plastic loading enterprises are generally in a relatively crude business model, the lack of R & D strength and links, a large number of small producers rely on the purchase of production equipment and raw materials for production, through the low cost of profit, low value-added, lack of foothold in the high-end market. And the production of raw materials required for products with better technical indicators mainly relies on imports from Taiwan, Japan, and other developed countries, forming a certain import dependency, which is not conducive to the stable development of the industry, and because the prices of plastic raw materials and international crude oil prices show the same direction of fluctuations, SMD plastic loading material prices are mainly determined by supply and demand, so the price fluctuations of raw materials will hurt the stability of earnings.

Plastic loading tape downstream boom is high

In 2016, China’s integrated circuit production grew 21% year-on-year, and discrete device production grew 11% year-on-year, with a high growth rate, and the downstream production growth will boost the demand for plastic carrier tape, which is favorable to the company.

Plastic carrier tape market space share

The spacing between the two holes on the plastic carrier tape is relatively wide, with 4mm, 6mm, 8mm, 12mm, 24mm, and other specifications, if we take the spacing of 8mm, based on the 2016 output of about 1,134,927 million semiconductor discrete devices, integrated circuits, LEDs, etc., the corresponding plastic carrier tape usage is about 9,080 million meters (about 1.8 billion of market share), the company’s share is less than 2%; (the chairman said that the company’s goal is to achieve a 30% market share within five years).

What kind of plan does the company have in the market of plastic carrier tape?

Company planning and strategic positioning, the strategic layout of the company’s future development is all kinds of plastic carrier tape, focusing on the development and production of high-end packaging carrier tape production.

The main industry layout of plastic carrier tape

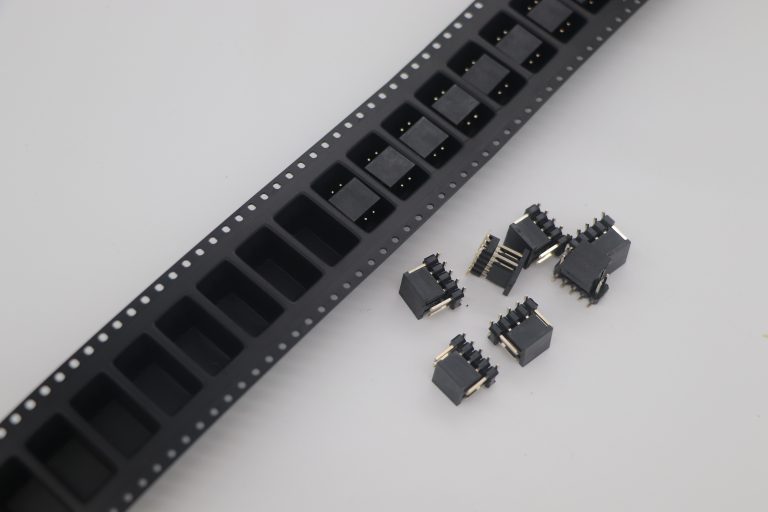

In the strategic layout of the plastic carrier tape, the company adheres to the same concept as the development of paper carrier tape, with the goal of high-quality carrier tape of the world’s leading plastic carrier tape manufacturers, first purchase black PC particles simply processed into plastic carrier tape and has achieved initial mass production, and then extended to the upstream, independent production of plastic particles, integrated development; plastic carrier tape gross margin of the core is mainly raw materials and equipment, the carrier tape The raw material also determines to a large extent the advantages and disadvantages of the packaging effect.

Current business situation of plastic carrier tape in the company

Since the performance carried out, growth is not bad, in more than 18 years of experience, we accumulate many customers.

Plastic carrier tape technology

The company now has SMD packaging roll tape automatic forming machine, automatic SMD packaging machine, semi-automatic packaging machine and carrier tape tension test machine. SMT components carrier tape packaging production machine, machine production precision, speed, high efficiency, easy to operate, simple to learn. It brings high efficiency and benefit to the carrier tape cover tape production and packaging. Our company has been committed to providing comprehensive solution services for electronics customers.

Plastic carrier tape production capacity expansion and planning

We are currently implementing a technical renovation project for the production line of plastic carrier tape for electronic component packaging, focusing on SMT consumables solutions, including tape and plastic rolls and SMT glue red glue, dispensing and solder paste application services and production expansion! Our goal is to provide excellent service to our customers.