Contact Your NewwaySMTC Representative Now! [email protected]

SMT Adhesive( SMT red glue)

Red Glue, SMT Adhesive Sale

Belonging to SMT material, we are professional SMT red glue manufacturer is red glue without odor and sticky strong, to ensure that no pieces fall off, no pulling. Hand brush, copper mesh, stencil, rubber mesh, machine printing, hand brush and other common. Push and pull force can reach more than 7 kg. The purpose of using red glue is to make the parts stick firmly to the PCB surface and prevent them from falling off.

Features: Fully customize to demands

SMD glue (SMD red glue) General information:

Use and precautions: After receiving the product,

please keep the material between 2 °C ~ 8 °C; The shelf life is 180 days.

Stored compounds must be thawed before use to avoid exposure. Heat at room temperature until no longer cool (about 3~4 hours). Do not heat in the oven.

Please use up materials within 72 hours.

Since the thawing and freezing cycle may include moisture from the material, avoid secondary refrigeration as much as possible.

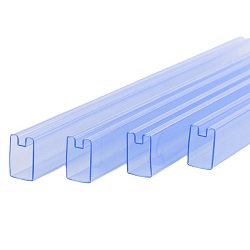

SMT red glue specifications for printing

SMT Red Glue Description: The products we provide can meet the environmental requirements of customers and comply with RoHS, REACH and ISO9001 standards.

Product Name:Red Glue SMT for Printing

Applicable models: HX600, HX608, HX610, HX880 Appearance color: pink / red

composition: epoxy resin

viscosity (25 ° C, at 5 rpm): 190Pa.s

Specified gravity: 1.28

This ratio: 6.8 (1 rpm / 10 rpm) Packing style: 200 ml / 1 piece or 300 ml / 1

piece

Storage conditions: The refrigerator storage temperature is 2 °C ~ 10

°C

2. Red glue features: red glue for Huamaoxiang printing is a thermosetting one-component

epoxy resin, SMT adhesive, especially suitable for SMD screen printing

process features include:

1. Stable adhesion can be obtained with various SMDs

2. Due to the appropriate viscosity and this ratio of screen printing, the diffusion of the printed

pattern cannot be obtained.

3. Convenient one-component adhesive with

excellent stability in the case of long-term storage.

4. Cured SMT adhesive has excellent high heat resistance and electrical

properties

3. Red glue curing conditions:

90 seconds after the PCB surface temperature reaches 130 °C, 60 seconds after the PCB board; The surface temperature has reached 150°C; When the higher the curing temperature and the longer the curing time, more muscle bond strength can be obtained. We recommend that you look for the best curing conditions for the temperature applied to the SMT The adhesive may sometimes vary depending on the size, material, etc. of the part mounted on the PCB.

SMT red glue hardening condition curve:

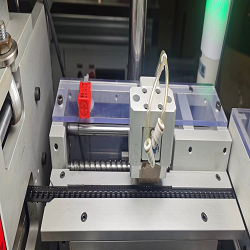

4. How to use:

1. SMT adhesive should be kept in the refrigerator (2 °C ~ 10 °C) to maintain its quality, only after room temperature (20 °C ~ 30 °C) can use the adhesive taken out of the refrigerator for at least 4 hours,

2. The bottom of the printing mesh should be cleaned in time to maintain a good printing shape3.Toluene

or ethyl acetate can be used to clean this SMT adhesive

Under the guidance of two junior chemistry doctors, we have dozens of colleges and universities and in-depth technical cooperation with China in the field of SMT adhesives and solder pastes. The R&D team composed of chemists, physicists, and electronic materials experts has been carrying deep basic materials in the electronic processing of high-end electronic adhesives and fast precision laser welding solder pastes. The products we have successfully developed are in a leading position at home and abroad, and are used in many leading enterprises and military enterprises in the industry.

| Weight | 200g, 360g |

|---|---|

| Number | 5pcs |