Contact Your NewwaySMTC Representative Now! DuncanLi@newwaysmart.com

Production method of carrier tape reel device

Due to the rapid development of the semiconductor industry, the carrier tape reel refers to the carrier widely used in ic devices, resistors, inductors, capacitors, and wafer packaging after the chip packaging, the carrier tape is usually coiled on the reel, the common reel in the prior art includes two discs set opposite to each other, the center of the disc is set with a connection axis, the carrier tape is coiled on the connection axis when used by the reel to extract the carrier tape can be. However, in the prior art, the carrier tape is usually prepared with insulating materials, and the friction between the carrier tape and the side wall of the reel when the machine extracts the carrier tape is likely to generate surface static electricity and thus break through the bearing device in the carrier tape.

What is the adaptation of the manufacturing method of the carrier tape reel device?

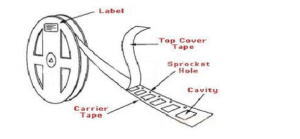

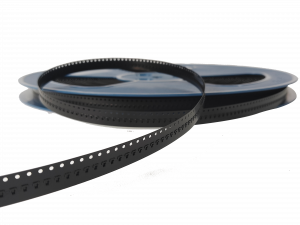

A carrier tape reel is a common packaging method used for electronic components such as surface mount devices (SMDs). The carrier tape reel consists of a plastic reel with a central hub and a continuous strip of plastic tape wound around it, which contains pockets or compartments for holding the individual components.

The manufacturing process for a carrier tape reel typically involves the following steps:

1. Design and tooling: The carrier tape and reel design is developed, and tooling is created to produce the tape and reel.

2. Material selection: The materials used for the tape and reel are selected based on their properties, such as mechanical strength, durability, and resistance to static discharge.

3. Ape extrusion: The plastic tape is produced by extruding the material through a die to create a continuous strip of the desired thickness and width.

4. Pocket formation: Pockets or compartments are formed in the plastic tape using a stamping or punching process, with each pocket corresponding to the size and shape of the individual components that will be loaded into it.

5. Component loading: The individual components are loaded into the pockets using automated equipment, which picks up the components from a tray or feeder and places them into the pockets on the carrier tape.

6. Reel winding: The carrier tape with the components loaded is wound onto the plastic reel, with a specific tension applied to ensure the tape is wound evenly and tightly.

7. Cover tape application: Once the carrier tape is fully wound, cover tape is applied over the top of the pockets to protect the components during transportation and handling.

8. Inspection and testing: The carrier tape reel is inspected and tested to ensure that the components are correctly positioned, the tape is wound correctly, and the cover tape is properly applied.

9. Packaging and labeling: The carrier tape reel is packaged in a suitable container and labeled with the relevant product information.

Overall, the manufacturing method of a carrier tape reel involves a combination of precision tooling, automated equipment, and quality control measures to ensure that the final product meets the required specifications and standards.