Contact Your NewwaySMTC Representative Now! [email protected]

Production method of cover tape and packaging body for electronic components

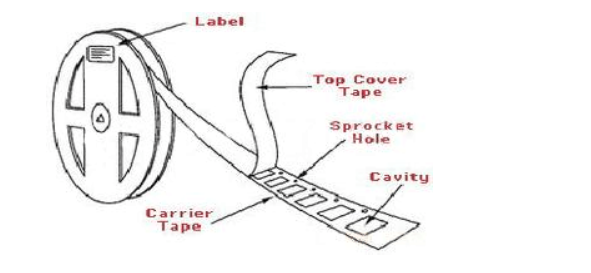

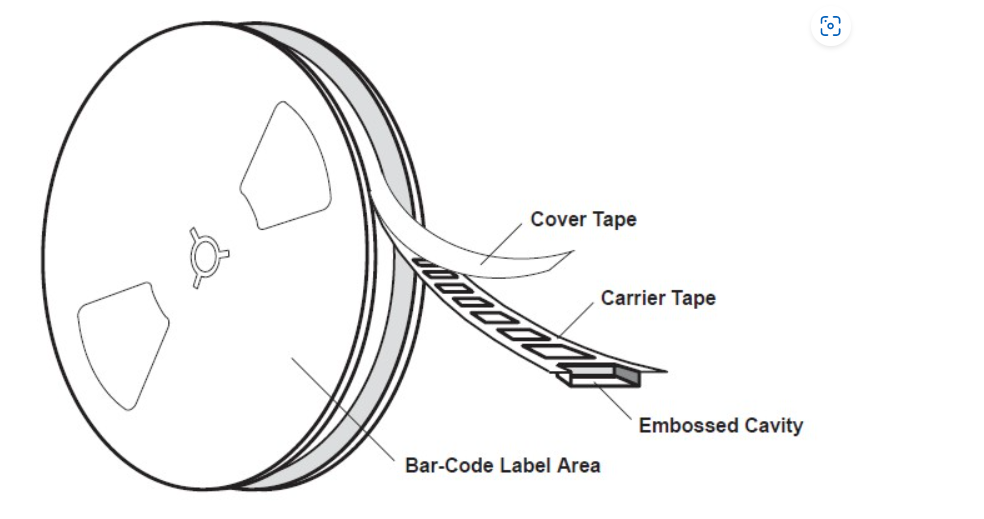

In the past, electronic components such as transistors, diodes, capacitors, and piezoelectric registers were packaged in a packaging body and heat-sealed, and then coiled on a paper or plastic reel and transported to a surface assembly area for electronic circuit substrates.

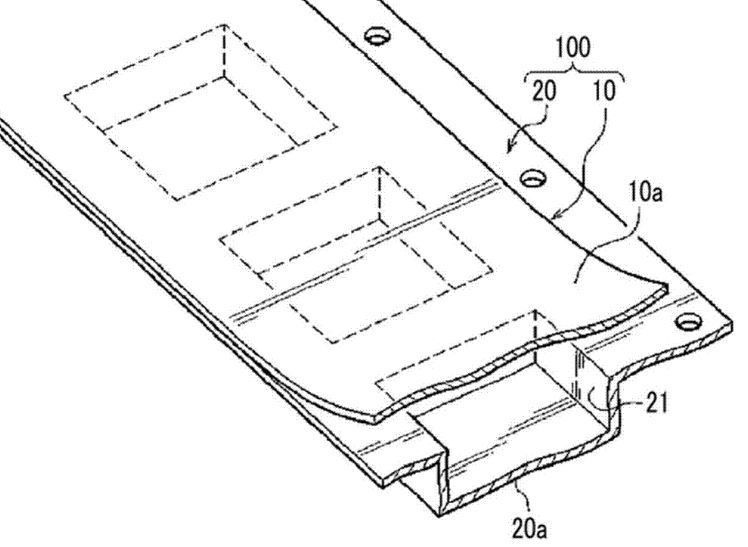

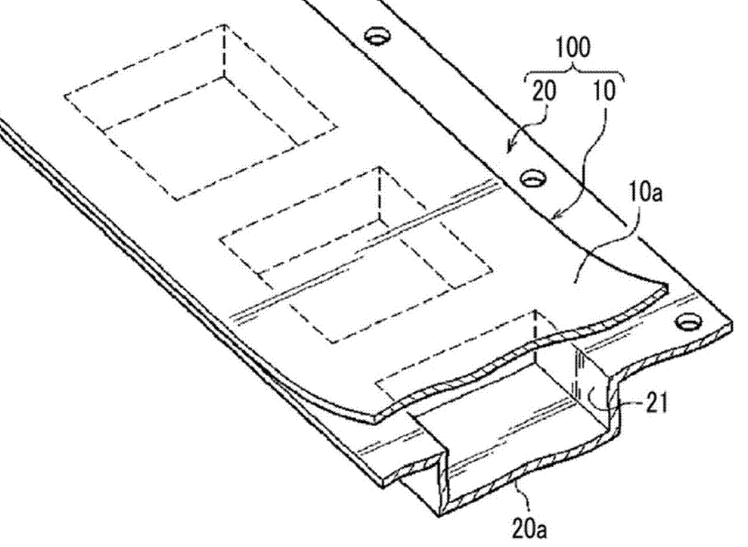

The packaging body consists of a carrier tape with a bag for storing the electronic part and a cover tape for sealing the carrier tape.

The electronic parts are removed from the bag formed on the carrier tape after the cover tape of the packaging body is peeled off in the work area, and are surface assembled to the electronic circuit substrate, etc. With the miniaturization of electronic devices in recent years, further miniaturization and high assembly of electronic parts are required. Therefore, in recent years, there is a tendency that electronic components are more susceptible to the effects of static electricity than before.

Cover tape for packaging of electronic parts, which does not cause contamination of sealed ironing parts due to flow out of the buffer layer and has excellent adhesion to the carrier tape

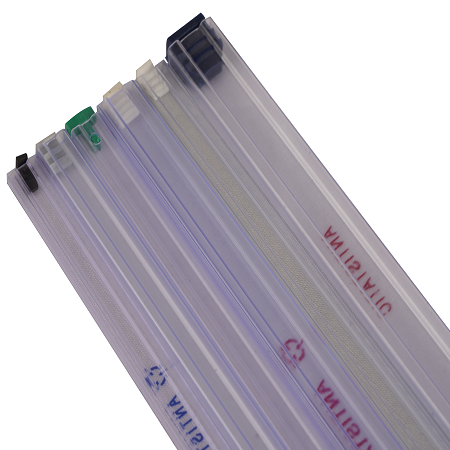

A cover tape comprising, in order, a substrate layer, an intermediate layer, an antistatic coating, and a heat seal layer, said intermediate layer comprising an ethylene-based polymer, an antistatic agent, and organic particles, wherein said ethylene-based polymer has a density of 0.90 to 0.94 g/cm3. By providing an intermediate layer with excellent antistatic properties and transparency, and adding an antistatic coating and an antistatic heat seal layer, the present invention enables the cover tape to achieve It has the requirements of high transparency and excellent antistatic effect, and also has the advantages of good buffering and good peel stability, which is especially suitable as the cover tape for packaging of micro electronic components.

How to package electronic parts packaging body

Electronic components such as semiconductor IC chips are packed with packaging materials to prevent contamination after they are manufactured and during the period before they are supplied to the installation process, and are stored and transported in a state where they are wound on a paper or plastic reel. In the packaging of the electronic part, a strip-shaped packaging material is used in a manner corresponding to the mounting process in which the electronic part is mounted on the substrate by an automatic mounting device, and the packaging material consists of a carrier tape with a plurality of concave storage grooves formed at prescribed intervals on a long strip of sheet material and a cover tape heat-sealed to the carrier tape.

The electronic parts are packaged in the carrier tape and the cover tape to form a protective layer

After the electronic parts are stowed in the stowage grooves of the carrier tape, the cover tape, which is used as a cover material, is overlapped on the upper surface of the carrier tape, and the ends of the cover tape are heat sealed continuously in the length direction with a heated sealing strip to form the electronic parts packaging body.

How the electronic parts are mounted and protected on the carrier tape and cover tape

The transported electronic part package is carried to the mounting process where it is mounted on the semiconductor substrate, the cover tape is peeled off from the carrier tape, the stowed electronic part is removed, and it is mounted on the semiconductor substrate. Therefore, it is important that the stripping of the cover tape is carried out smoothly. Moreover, with the recent high-speed mounting, the peeling speed of the cover tape has increased and the peeling strength of the cover tape is required to be improved.

From the viewpoint of obtaining a cover tape whose peel strength is not easily influenced by the peel speed and whose peel strength does not increase abnormally at high speed mounting even with the previous peel strength management method, we have developed a cover tape that has a base tape that is capable of being mounted at a high speed. A cover tape having: a base material layer having a specified thickness and a tensile elastic modulus; and a heat seal layer containing a polystyrene-based resin and a polyethylene-based resin and a fatty acid amide, and having a specified thickness and a tensile elastic modulus.