Contact Your NewwaySMTC Representative Now! DuncanLi@newwaysmart.com

PS transparent carrier sheet, for the rapid development of the packaging and testing industry not only brings benefits but also improves competitiveness

PS transparent carrier tape sheet is becoming increasingly popular in the packaging and testing industry due to their versatility and ability to improve the overall efficiency of the process. These sheets offer high transparency and provide a secure method for packaging and protecting small electronic components, such as semiconductors, LEDs, and resistors.

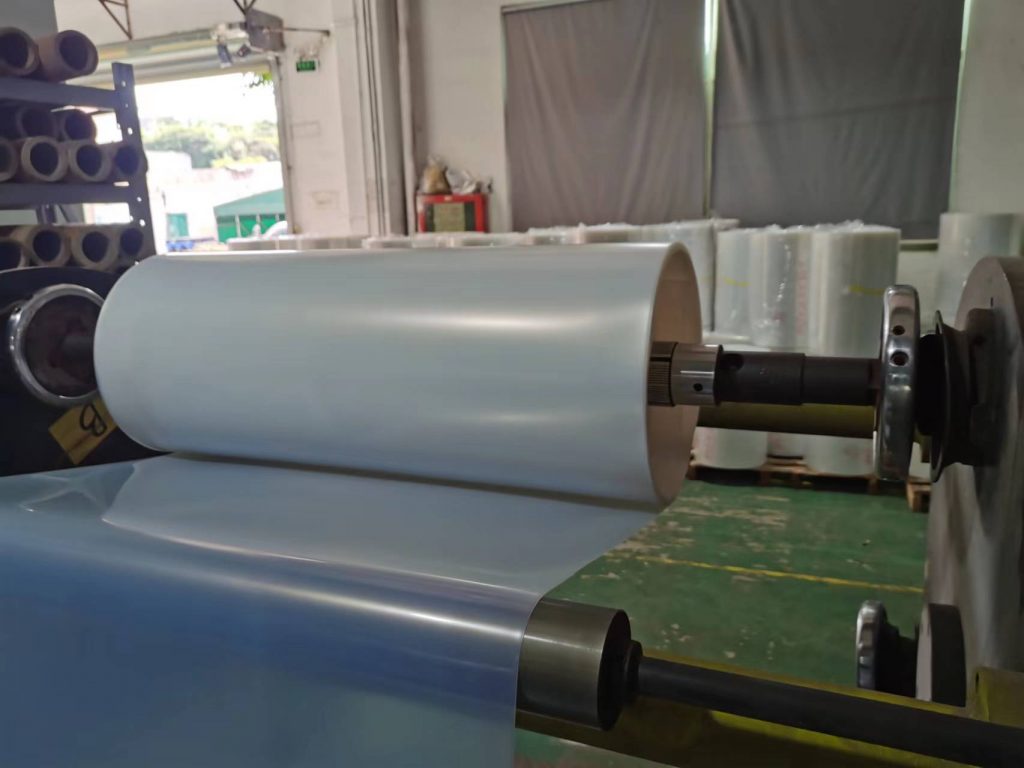

What is PS transparent carrier sheet?

A PS transparent carrier sheet is a type of film or sheet used in various printing and crafting applications, particularly in the production of custom decals or stickers. “PS” refers to polystyrene, the material used to make the carrier sheet.

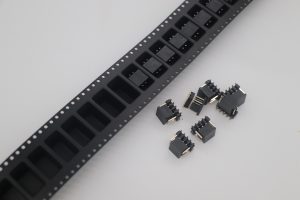

PS carrier tape sheets are commonly used in the manufacturing and packaging of electronic components that are delivered in tape-and-reel format.

The carrier tape is a strip of plastic with pockets or cavities that hold individual components, such as integrated circuits or resistors. The carrier tape is wound onto a reel, and the components are fed to automated assembly machines that place them onto printed circuit boards.

What are the benefits of PS transparent carrier sheet for the rapid development of packaging industry?

One of the advantages of using a PS transparent carrier sheet is that it is a thin and flexible material that can conform to the shape of the surface it is being applied to. This makes it ideal for producing custom decals and stickers that have intricate or detailed designs. Additionally, the transparency of the carrier sheet allows for greater accuracy when aligning the design on the surface it is being applied to.

PS transparent carrier sheets (made of polystyrene) have several benefits for the rapid development of the packaging industry. Some of these benefits include:

1. Clarity: PS transparent carrier sheets have high transparency, which allows customers to see the product inside the packaging. This is important for products that need to be visible to the customer, such as food or cosmetic items.

2. Durability: PS transparent carrier sheets are strong and have good impact resistance, which makes them ideal for protecting products during shipping and handling.

3. Flexibility: PS transparent carrier sheets can be easily shaped, molded, and cut to fit different packaging requirements. This allows for a wide range of packaging designs and shapes.

4. Cost-effective: PS transparent carrier sheets are relatively inexpensive to produce, which makes them an affordable option for a variety of packaging applications.

5. Environmentally friendly: PS transparent carrier sheets are recyclable and can be reused, which makes them a more sustainable option compared to other packaging materials.

The benefits of PS transparent carrier sheets make them an attractive option for companies in the packaging industry looking for a versatile and cost-effective material that can enhance the customer experience while also being environmentally friendly.

PS transparent carrier sheet for rapid development of packaging industry brings high competition

The use of transparent carrier tape sheets can greatly enhance the competitiveness of the packaging and testing industry by reducing costs and increasing productivity. They are highly efficient in terms of material usage, as they allow for optimal space utilization and can be easily cut to fit the required size. Additionally, these sheets are easy to transport and store, which can further improve the overall efficiency of the process.

In terms of testing, transparent carrier tape sheets can also facilitate the inspection of components by providing a clear view of the product, allowing for easy identification of defects and errors. This can help improve the quality control process and ensure that only high-quality components are released to the market.

Overall, the adoption of transparent carrier tape sheets can help companies in the packaging and testing industry increase their competitiveness by providing a cost-effective, efficient, and reliable solution for packaging and testing electronic components.