Contact Your NewwaySMTC Representative Now! [email protected]

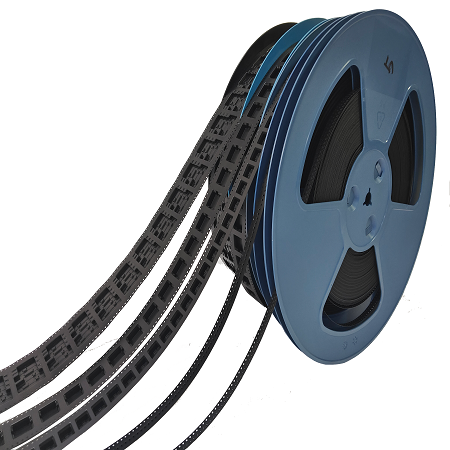

SMD carrier tape packaging is fully inspected and tested for quality assurance to ensure customer peace of mind

SMD carrier tape packaging is designed to achieve excellent and perfect quality.

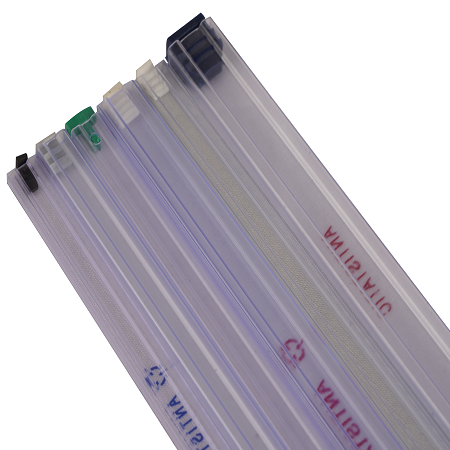

Our company produces more than 10,000 meters of carrier tape per month, and can produce any shape of carrier tape of any specification. SMD carrier tape packaging includes many types, such as nut carrier tape packaging carrier tape, shrapnel carrier tape packaging, shrapnel OEM carrier tape packaging, inductor carrier tape packaging, ic carrier tape packaging, etc.

SMD carrier tape packaging full inspection size, shipping quality assurance production capacity, can adapt to the different needs of customers

We must not only keep improving in process management, but also pursue the production of perfect SMD carrier tape quality in terms of instrument inspection and comprehensive consolidation. Improve the yield of production and the technical ability of production to ensure stable quality.

SMD carrier tape packaging tension test instrument

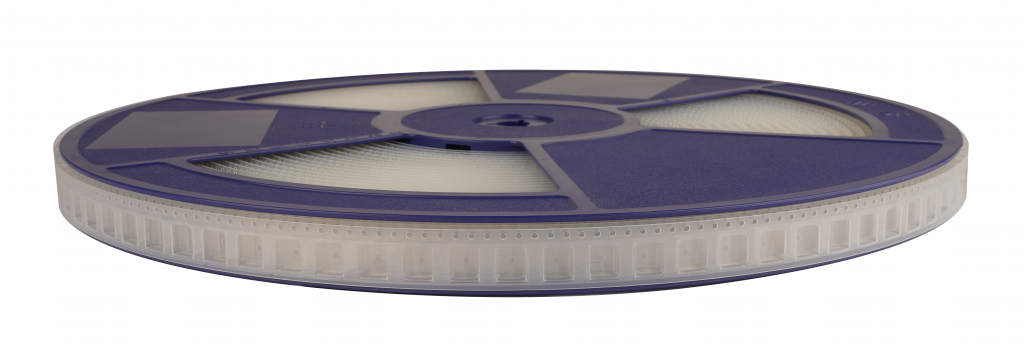

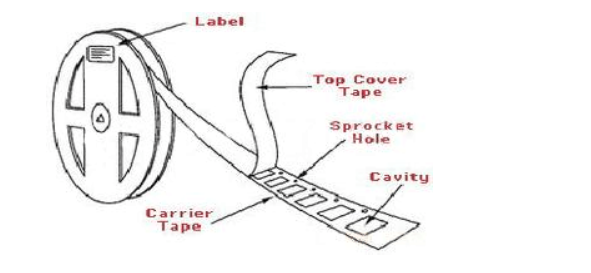

SMD carrier tape is a kind of tape product applied in the field of electronic packaging, it is used together with the cover tape (top sealing tape), the electronic components such as resistors, capacitors, transistors, diodes, etc. are carried and stored in the pockets of the carrier tape, and by sealing the cover tape above the carrier tape to form a closed packaging, used to protect the components from contamination and damaged in transit. When the electronic components are affixed, the cover tape is stripped, and the automatically affixing equipment, through the precise position of the index hole of the carrier tape, takes the components held in the pocket out in order, and installs them on the integrated circuit board (PCB board). Therefore, while production and use of carrier tape products, whether the index of peel strength is acceptable or not has a great impact.

SMD carrier tape packaging tension functions and uses

1. Conform to the ANSI/EIA-481-D standard on the peel strength test requirements design.

2. Manual control or PC control can be used.

3. Adopt Japanese original/domestic (1kg) tension test head (optional), accurate test value.

4. The test value adopts RS232 digital signal transmission to ensure no error in data conversion.

5. Software operation using WINDOWS interface, easy to operate, convenient, professional data format, test results can not be modified, highly credible.

6. Sampling data can be set to delay reading, real-time display of test results, can set the upper and lower limits of tension, automatic judgment can print test results. Data can be stored to establish a historical database.

7. The peeling speed is displayed by LCD.

8. According to customer needs to do professional development, the price is negotiable.

9. Computer and tensiometer linear connection, always record the tensile force data, and timely data in the form of curves presented on the screen, the test is complete. Automatically give the tension of the great value, small value, tension range, average value, root mean square value, standard deviation, variance, etc., convenient data statistics.

SMD carrier tape packaging is to ensure the protection film of components

This is because when chips, semiconductors and other electronic components of materials in the process of transportation and assembly, the most vulnerable to static electricity and physical damage, even just a slight friction, movement will generate static electricity. The ultra-fine static electricity generated by the slight shaking and friction between components and components can also lead to damage to most of the component materials, which is fatal. This explains the particular importance of SMD carrier tape packaging service solutions. When electronic components are mounted, the cover tape is peeled off and the automatic mounting equipment removes the components held in the pockets in sequence through the precise positioning of the carrier tape index holes and mounts them on the integrated circuit board (PCB board). In the use and production process between the carrier tape and the cover film peeling index is very with important. It is used to test whether the peel strength of the cover tape meets the requirements of the EIA standard. The tensile strength tester enables the SMT process to be quality assured upfront.

SMD carrier tape packaging quality assurance

Our products are strictly enforced by the international quality management certification system, and all materials are monitored and certified by SGS for environmental protection, which is more environmentally friendly and reassuring. Polystyrene and ABS (acrylic-butadiene-styrene copolymer resin) carrier tape. In addition, there are also a small amount of PET. APET and other materials prepared carrier tape, high glass transition temperature, good heat resistance, PS material mechanical strength than PC material is low. PS (Polystyrene so sometimes and ABS material into a three-layer composite sheet to improve the tensile strength of the carrier tape is more suitable for the preparation of large-size pockets, according to the way the carrier tape molding points: according to the pocket molding According to the way the pockets are formed, they can be divided into two types of forming: intermittent (flat molding) and continuous (roller rotation). Numerical indication of the device in the pocket is damaged when the voltage applied, rigid material packaging can provide appropriate gaps for the device ESD protection and physical protection can receive better results. SMD carrier tape packaging, bags or boxes important feature is their antistatic properties.

SMD carrier tape packaging OEM packaging

SMD carrier tape packaging manufacturers direct sales, can accept small quantities of custom, can take expedited orders, fully meet your needs. Because antistatic agents have certain conductive properties, they are under the conditions of proper humidity. They are capable of discharging static electricity by dissipation. In practice, however, the latter property may be more easily valued. Thus it becomes the main indicator for assessing antistatic materials, but antistatic carriers have a more important function. This is why they are called antistatic materials, and there are three different types: materials that are treated with an antistatic agent surface, synthesized with an antistatic agent to form an antistatic film on the surface, and materials that are inherently antistatic. Contribute to the reduction of friction voltage antistatic agents can also reduce friction commonly used antistatic agents can reduce the static electricity of many materials.

SMD carrier tape packaging is used in the production of electronic components SMD industry. So electronic components are well protected, and we are good for the production of the whole test is conducive to the protection of quality, conducive to let customers know our quality, with confidence, the demand for our products is large.