Contact Your NewwaySMTC Representative Now! DuncanLi@newwaysmart.com

SMD carrier tape production and packaging process requirements

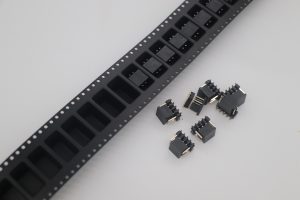

SMD carrier tape is a strip that includes elements such as pockets, pocket holes and index holes, and is an indispensable key material for chip electronic component manufacturing and circuit board placement assembly. What are the process requirements for the production and packaging of SMD carrier tape?

SMD carrier tape production process requirements and advantages

SMD carrier tape is used in the field of electronic packaging tape products, it is used in conjunction with the adhesive tray and the upper tape. The materials used in the production of carrier tapes include two main types of materials: plastic (polymer) and paper. The carrier tape made of paper is also called paper tape, so we will not introduce it here. The next step is to look at the process requirements and advantages of SMD carrier tape production.

SMD carrier tape production process requirements

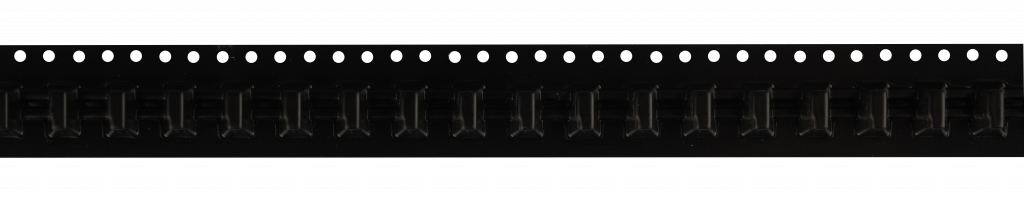

1. SMD carrier tape production in the manufacturing process of the tape, all the way to the material preparation system, there is always a separation tape. The role of the tape is to collect the raw material on the basis of a plastic garden board when making the tape

2. The collection of the raw material should be done simultaneously with the loading tape and the separation tape. Since the bearing tape is a plastic sheet containing bags, the rubber and plastic product snow pieces will be redial during the packaging process, resulting in the bearing tape becoming scrap iron, and the separation tape will be fully utilized.

3. Bearing tape as a packaging product, in the manufacture of rubber and plastic products and bearing tape applications will inevitably hair cattle bending. Too much bending can cause the tape to break. If the tape breaks during mass production, it will lead to production blockage.

Therefore, the bending test of the bearing tape requires us to test the bending time after the manufacturing of the bearing tape is completed to ensure that the bearing tape is molded for various applications. The bending of the bearing tape is performed by clamping the bearing tape on the test apparatus for continuous oscillation of the tube part of the bending experiment, automatic counting, saving the load tape bending time

4. Lift pallet for bearing tape pallet, conveyor tape carrying packaging products, under various conditions such as transportation, the load pallet will be affected by various forces, tensile strength is one of them.

SMD carrier tape production process advantages

1. The bearing tape also needs to be used with the cover tape to carry electronic components. Carrier tape is mainly used for SMT software packaging of electronic components. Carrier tape and cover tape combined with the production of packaging, electronic components are not easy to damage and collision.

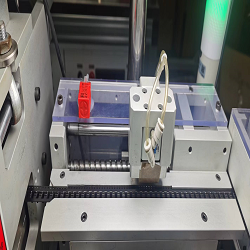

2. When the electronic components are removed, the cover will be removed. SMT machines and equipment will remove the components in the stamped load tape one by one through the precise positioning holes of the stamped load tape and install them on the integrated circuit chips, thus producing a complete electronic control system.

3. To better maintain electronic components from damage by electrostatic induction. Some fine electronic components have specific requirements for the anti-static level of the stamped parts. According to the anti-static level, the stamping parts can be divided into three types: conductive type, anti-static type (electrostatic induction loss type) and insulating layer type.

4. Easy to carry, ensure efficiency, product type, total length, charging and maintenance, load-bearing transportation, packaging features.

SMD carrier tape packaging production process requirements

The rapid development of today’s electronics industry, modern enterprises to produce small, more sophisticated electronic products will be an inevitable trend, electronic components will also be refined, small. As an important downstream industry in the electronics industry, SMD carrier tape will also follow the trend of electronic components, the production of fine, small SMD carrier tape to dominate the entire market. Therefore, the production process of SMD carrier tape packaging has become more and more demanding.

What is the role of carrier tape protection?

In the production of the carrier tape until the receipt system software, there has been isolation tape storage. Carrier tape production must be rubber tray can be collected, the collection of materials is necessary to carry out a separate carrier tape and isolation tape, because the carrier tape is a plastic sheet with pockets, when the rolled part of the molding will be added together, resulting in the deformation of the carrier tape become scrap, all carrier tape production isolation tape also has the effectiveness.

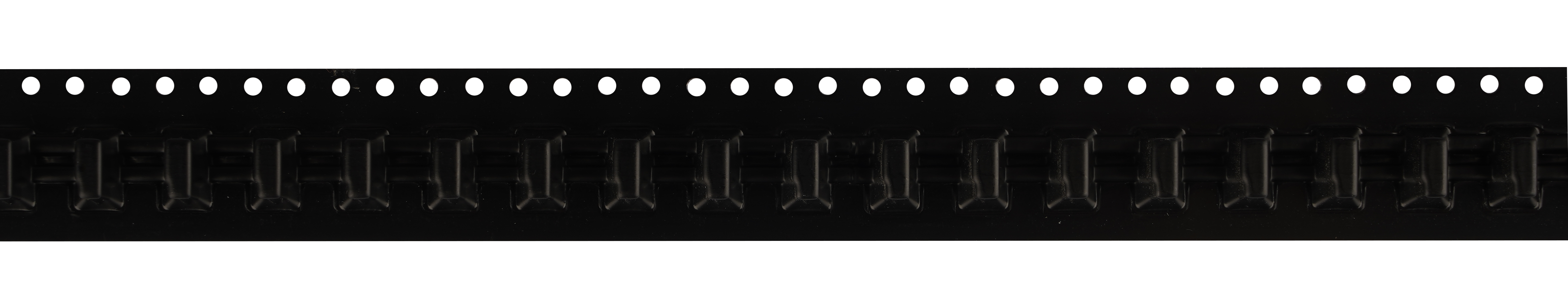

SMD carrier tape is an electronic packaging material composed of plastic tape

Its molding principle is through the carrier tape molding machine heating part of the raw material of leather products to a certain temperature, through the molding mill injection molding, through the hardware mold punching

Then, it is pulled forward by pulling the tape partly. When the set strain rate is done, the laser cut roller barrel posture to carry out the production of rolls, followed by the secret medicine through the release of rolls.

SMD carrier tape packaging is mainly used for SMD insert operation of electronic components.

When incorporated with cover tape applications, electronic components are stored in the carrier tape packaging, and the packaging is produced with the carrier tape cover tape to maintain the electronic components from environmental contamination and impact.

In the electronic components work, tear off the cover tape, patching machine equipment through precise and accurate positioning of the carrier tape accurate positioning holes, successively take down the components in the tape, Anzang in the circuit board, produce a detailed electrical control system.

SMD carrier tape packaging Pu bragging with dry packaging integrated circuits, semiconductors, quartz crystal resonators, oscillators, connectors and other electronic components packaging. Cell phone screen pay frame and other posting electronic components of the medium, in addition to accurate, precise and rapid, carrier tape can also be fully considered natural environment cold, heat, magnetic, ultraviolet light, anti-static and environmental protection and other electronic characteristics of the provisions of the Hopping F1A standard.

The production of SMD carrier tape will pay more attention to environmental protection, in line with environmental requirements, pollution-free green electronic product packaging materials will be greater attention. So that the high demand for SMD carrier tape production as well as packaging process has also become a trend, which will allow producers to pay more attention to quality in order to better attract customers.