Contact Your NewwaySMTC Representative Now! DuncanLi@newwaysmart.com

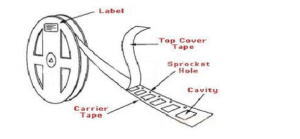

SMD Packaging Storage and Handling

Surface mount packaging, referred to as SMD packaging, will also encounter many restrictions in our substantive operations.

That SMD packaging restrictions will be which some of them

As we all know, during reflow, SMD is exposed to high temperatures and internal moisture from the atmosphere can evaporate. Vapor pressure can cause internal delamination or separation of the packaging material from the die, lead frame, and substrate interfaces and damage the bonding lines. The most severe of these pressures can cause cracks to form in the die compound, leaving the die exposed to the external environment. These damages can directly or indirectly affect device reliability. With the following guidance, semiconductor customers can avoid similar problems.

Description of dry packaging in SMD packaging

Dry packaging consists of desiccant, a moisture indicator card (HIC) sealed in a moisture barrier bag (MBB), and a bar code label. MBBs provide ESD protection, the required mechanical strength and flexibility, penetration resistance, and heat sealability. The desiccant in each package guarantees an internal relative humidity of less than 10% and a temperature of 25°C.

Storage Requirements and Time Restrictions for SMD Packages Removed from Dry Packages

The humidity indicator card provides customers with a simple and effective way to verify the humidity level inside the package using color spots and dry bake details.Storage Requirements and Time Limits for Removal from Dry Packages

When the SMDs are removed from dry packaging, each SMD is classified according to the MSL to determine the appropriate packaging, storage, and handling requirements. Table 1 lists the MSLs, shop life, packaging, storage conditions, and shop life prior to reflow process.

Storage Requirements and Time Restrictions for SMD Packages Removed from Dry Packages

If the customer is unable to install the SMD within the specified time frame or if the plant environment exceeds the maximum allowable temperature or humidity, the customer can maintain shop life by reducing moisture absorption through the following safe storage methods.

Dry packaging The SMD dry packaging has a minimum shelf life of 12 months from the date of sealing and is stored at <40°C/90 % RH.

Dry gas storage cabinets, oxygen or dry purge gas storage cabinets with low relative humidity (25±5°C) can recover the required humidity within 1 hour by opening or closing the storage cabinet door.

10% RH dry cabinet According to J-STD-033B.1, SMDs that are not sealed in MBB can be stored in a dry atmosphere cabinet with ≤ 10% RH (not exceeding the maximum time). If the time limit is exceeded, baking is required to restore the shop life.

What will be the drying procedures and requirements for SMD packages?

SMD that cannot be stored or handled as specified must be oven dried to restore shop life prior to reflow. They are then sealed again in a desiccant-supplied MBB to reset shelf life.

Caution.

Considerations for SMD packaging

For all dried SMD, the customer must adhere to the same storage requirements and time frame.

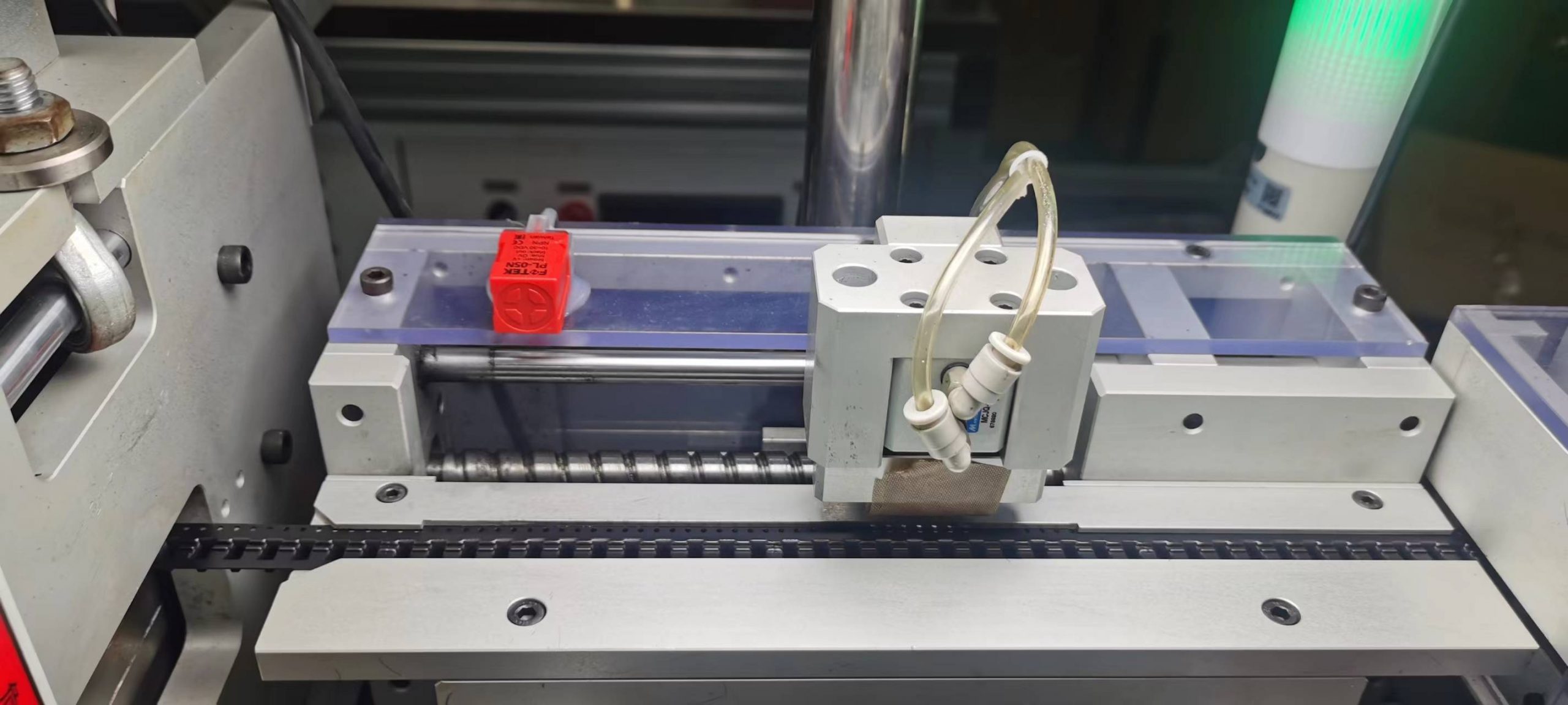

Attention to SMD packaging during assembly

The reflow process may involve single or multiple processes during the assembly process. Placement/removal rework is performed on individual components. When the MBB is enabled, all SMDs in the package are subjected to the reflow process before being sealed in the MBB or stored in a dry cabinet according to safe storage requirements before the specified shop life expires. If the shop life or specified plant environment is exceeded, refer to the drying procedures and requirements. During reflow, ensure that the temperature rating on the SMD barcode label is not exceeded, otherwise product reliability will be compromised.

Note SMD package interior and exterior matters

In IR and IR/convection reflow processes, the component body temperature must be confirmed; this temperature may differ from the tin ball temperature.

JESD22-A113 thermal reflow curve parameters should be followed. Although the component body temperature is the most important parameter in the reflow process, other parameters should be considered as they also affect component reliability.

If several reflows are required, ensure that the SMD (loaded or unloaded) does not exceed the shop life before the last reflow. If any component on the board exceeds its shop life, it needs to be baked prior to the next reflow.

From the above we can know that we clearly understand the impact of the restrictions brought by SMD packaging, so as to go to avoid problems and provide customers with high quality and packaging services, providing a satisfactory answer.