Contact Your NewwaySMTC Representative Now! [email protected]

SMT Carrier Tape Manufacturer——The Need for Constant Temperature and Humidity Testing of Carrier Tape

Newwaysmart needs to do temperature and humidity testing on our carrier tape because we have always been committed to the idea of quality first. We have been conducting tests that other companies have not, to really ensure that our carrier tape products are truly high quality products, and we have been working hard to achieve our goal. Doing temperature and humidity tests on the carrier tape is our way of testing our carrier tape products from all aspects of environmental mechanics, so that our products really meet the EIA standards and are never faked. Customer satisfaction is the only criterion to test us.

SMT carrier tape manufacturers why they need to do constant temperature and humidity test on the carrier tape

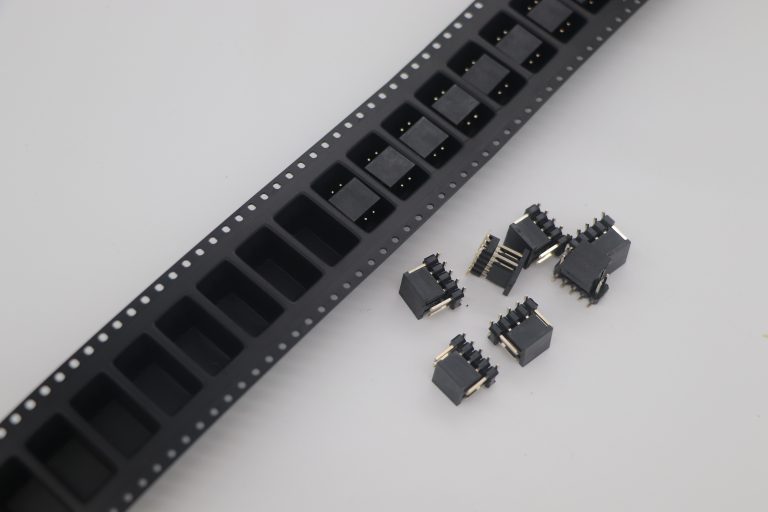

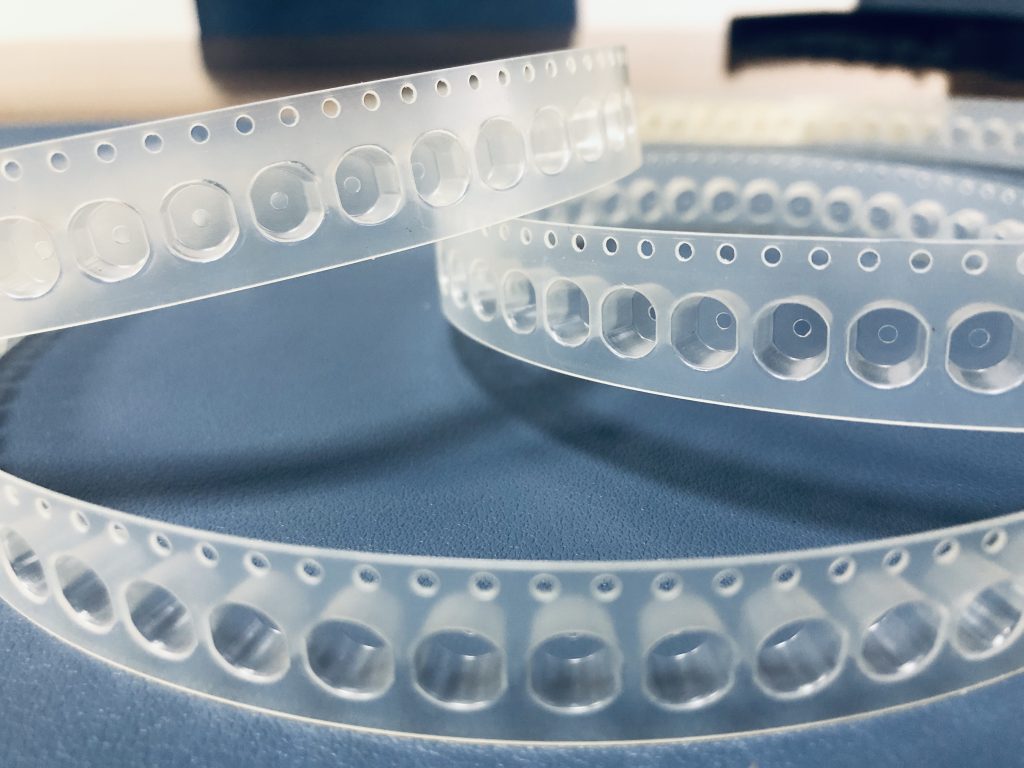

Newwaysmart specializes in precision carrier tape forming machine, carrier tape tensile testing machine, automatic SMD packaging equipment customization, carrier tape, cover tape, red glue and SMD electronic packaging materials to develop SMD type sealing tape as a benchmark, and actively develop various types of IC, electronic components, precision hardware stamping parts, SMD components, connectors and other special carrier tape according to customer needs. Carrier tape to do constant temperature and humidity, is the product diversification, to meet the needs of the market.

What is the constant temperature and humidity test to be done for carrier tape

Constant temperature and humidity test equipment is a kind of test equipment that imitates the natural environment, mainly for testing products to simulate weather conditions for aging tests. Carrier tape as a packaging material for loading materials, also need to do constant temperature and humidity test, in order to test the carrier tape products in different temperature conditions, the material in a specific temperature and humidity conditions can withstand the physical withstand value, that is, the carrier tape in different stages of the ambient temperature under the stress of the screening, so that the carrier tape material can withstand a different range of temperature test, prove that the carrier tape products are qualified.

Carrier tape in the detection of constant temperature and humidity

Carrier tape conveyor tape is a kind of electronic packaging, with dry precision snowflake parts packaging, its quality requirements are relatively high, there may be many people think that the carrier tape this packaging material as long as the molding can be, the packaging is no problem. In fact, the carrier tape as a carrier, not only to consider the load-bearing capacity of the items, but also to consider the tension in automated production. As well as whether the packaging will be damaged in different environments, even during transportation, many aspects such as stacking, drop impact, and transportation vibration will be considered. Therefore, from environmental testing to mechanical testing, we need to improve step by step.

Along with the development of industry, factories are being automated as the cost of labor rises. Under the movement of the mechanization era, the supply of loading materials has become a key issue in the automation conditions, often the anti-static load generated during electronic manufacturing with this solves the problem of loading operations, our load-bearing system is composed of a flat plate machine, round wheel machine, granulator continuous, speeding up the efficiency of automated production, our tape machine in the safety detection, which can grasp the feeding time more precisely. Now the carrier runs in various fields of the electronics industry, from the hardware is leading, capacitors, inductors, electronic components and many other industries, in short, this new type of carrier packaging brings us convenience.