Contact Your NewwaySMTC Representative Now! [email protected]

The role and function of the carrier tape stripping test

A carrier tape stripping test is a type of test used to evaluate the strength of the bond between the carrier tape and the components stored on it. The test involves applying a force to pull the components off the tape to determine the amount of force required to separate the two. Carrier tape stripping test is used to ensure that the components will remain securely attached to the carrier tape during transport and storage, and that they will not fall off and become damaged or lost. The results of the carrier tape stripping test are used to optimize the design of the carrier tape and the components, and to determine the best manufacturing processes to ensure a strong bond between the two.

The role of carrier tape stripping

Carrier tape stripping refers to the process of removing the protective material that surrounds electronic components on a carrier tape. This process is necessary to make the components accessible and usable for assembly.

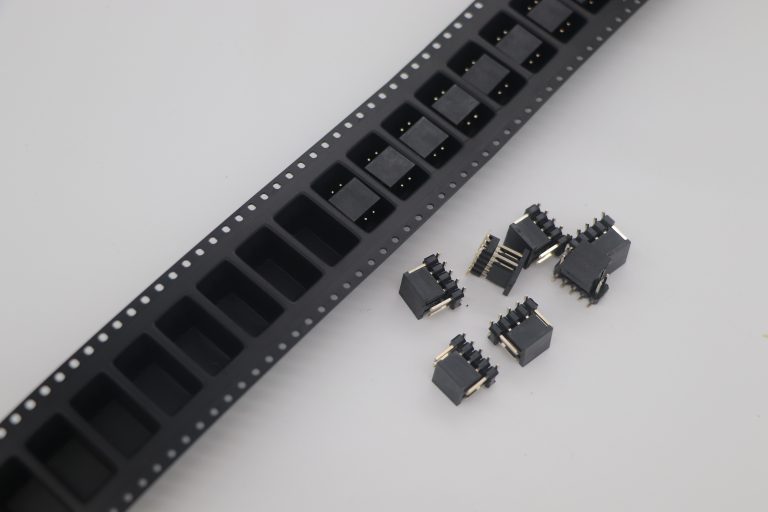

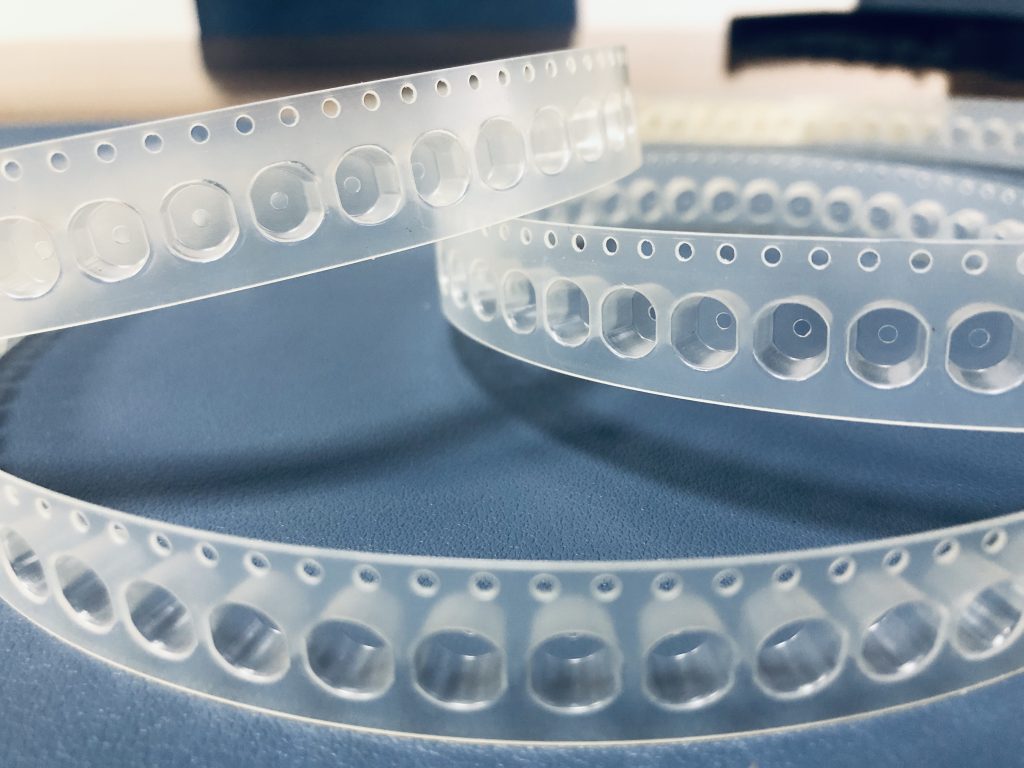

In electronic assembly, components are often packaged and transported on a carrier tape, which is a continuous reel of plastic material with pockets to hold the components. The pockets are covered with a protective material, such as a clear plastic cover, to protect the components during transportation and storage.

Before the components can be assembled, the protective material must be removed or stripped off, which is where the term “carrier tape stripping” comes from. The stripping process is usually done manually or with specialized machines, and it involves exposing the components in the pockets so that they can be picked up and placed onto the circuit board.

The accuracy and efficiency of the carrier tape stripping process are important for ensuring the quality and reliability of the final assembly. Improper stripping can result in damage to the components, which can lead to defects or failures in the final product.

Overall, the role of carrier tape stripping is to provide access to the components packaged on a carrier tape so that they can be used for electronic assembly.

Carrier tape stripping function

The function of carrier tape stripping, also known as carrier strip or tape and reel, is to provide a convenient and efficient way to transport, store, and handle electronic components.

Carrier tape is made of a continuous reel of plastic material with pockets to hold the components. The pockets are designed to protect the components from damage during transportation and storage, and they also make it easier to pick and place the components onto a circuit board during the assembly process.

The use of carrier tape provides several benefits:

1. Protection: The pockets on the carrier tape protect the components from physical damage, contamination, and moisture.

2. Convenience: Carrier tape provides a compact and organized way to store and transport large quantities of components, reducing the risk of loss or damage.

3. Efficiency: The use of carrier tape in the assembly process makes it faster and easier to pick and place components onto a circuit board, which can increase the overall assembly efficiency.

4. Automation: Many modern assembly processes use machines to pick and place components from the carrier tape, which further increases the efficiency and reduces the risk of human error.

Overall, the main function of carrier tape is to provide a reliable and efficient method for handling electronic components in the assembly process.

The role of the carrier tape stripping tester

The carrier tape stripping tester is a specialized machine used to evaluate the strength and reliability of the tape-to-component connection in carrier tapes used in the electronic manufacturing industry. The carrier tape is an integral part of the packaging of electronic components, and it is important that the tape-to-component connection be strong enough to hold the components securely in place during storage, handling, and assembly.

The carrier tape stripping tester operates by applying a force to the component and measuring the resistance of the tape-to-component connection. The test results are used to determine the strength of the connection and the ability of the tape to hold the components securely. This information is critical for ensuring the reliability and performance of the electronic product in which the components are used.

The carrier tape stripping tester typically consists of a test fixture that holds the carrier tape and a load cell that applies the force to the component. The test results are displayed on a monitor and can be recorded for analysis. The use of a carrier tape stripping tester helps manufacturers to ensure that their components are packaged in the most effective and reliable manner possible.

Carrier tape testing

The top of the carrier tape is the cover tape, in use will automatically peel off, in order to make the product fit on top of the board.

So the peeling force of the carrier tape is more important, too small in the transportation process is easy to loosen the product scattered. The force is too large, in the production line is not easy to peel. So it is necessary to carry out peel force test on the carrier tape. The market is called carrier tape stripping test, machine